Cap Sealing Wads

Cap Sealing Wads Specification

- Product Type

- Cap Sealing Wads

- Type

- Sealing Wads

- Style

- Round Discs

- Size

- Varies (Customizable)

- Color

- White Silver

About Cap Sealing Wads

Exceptional Versatility for Advanced Sealing Applications

Cap Sealing Wads are meticulously engineered to accommodate a broad array of application surfaces, including PET, HDPE, PP, and glass closures. Suitable for use on both manual and automated sealing machines, these wads provide an ideal match for industries like foods, chemicals, cosmetics, and pharmaceuticals. The application media is diverse, ensuring secure seals for various container types. Their round design is standard, but custom shapes are available, allowing a seamless fit and ensuring optimal leak-proof performance every time.

Expansive Market Reach and Certified Quality Assurance

Our Cap Sealing Wads enjoy a monumental presence in both domestic and international marketplaces. With a commitment to quick dispatch and prompt shipment, were positioned to serve major export markets across Asia, Africa, and Europe, alongside strong distribution in Indian metros and emerging cities. Clients gain additional assurance through our stringent certifications, ensuring all products meet global regulatory compliance. Take advantage of our offer for certified, reliable sealing solutions delivered efficiently to every corner of your operational landscape.

FAQs of Cap Sealing Wads:

Q: How can Cap Sealing Wads be customized to suit specific application requirements?

A: Cap Sealing Wads offer extensive customization, including thickness (0.8 mm to 1.5 mm), shape, size, printing, adhesive type, and sealing mechanism. This ensures optimal compatibility with unique container types, closure systems, and application environments.Q: What are the different sealing types available for these wads?

A: The product range includes induction heat seal, pressure-sensitive, and two-piece wads. Each type is suited to specific closure designs and operational preferences, providing secure and tamper-evident sealing for your bottles.Q: Where are Cap Sealing Wads primarily used, and what industries benefit from them?

A: These sealing wads are suitable for PET, HDPE, PP, and glass bottles, benefitting industries such as food, pharmaceuticals, chemicals, and cosmetics, where product integrity and tamper resistance are paramount.Q: What is the typical process for applying these Cap Sealing Wads?

A: Application involves placing the wad onto the bottle closure and using induction sealing or pressure to bond the wad to the container. The process is compatible with both manual and automated machinery.Q: When should I consider using a two-piece wad versus a single-piece induction seal?

A: A two-piece wad is typically recommended for applications requiring additional cushioning or enhanced sealing strength, while single-piece wads offer reliable standard sealing for most closures and production lines.Q: What benefits do moisture-resistant and odorless sealing wads provide?

A: Moisture-resistant and odorless properties help preserve the quality and freshness of products, prevent contamination, and ensure compliance with food and pharmaceutical safety standards.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Packaging Material Category

Induction Sealing Wads

Minimum Order Quantity : 12000 Pieces

Type : Other, One Piece & Two Piece Wad

Color : Silver, White, Custom Print

Product Type : Other, Induction Sealing Wad

Hardness : Other, Medium

Dimension (L*W*H) : Custom as per requirement

Vacuum Pouch

Minimum Order Quantity : 100 Kilograms

Type : Other, Flexible packaging pouch

Color : White

Product Type : Other, Vacuum Pouch

Hardness : Other, Soft and flexible

Dimension (L*W*H) : Customizable as per requirement

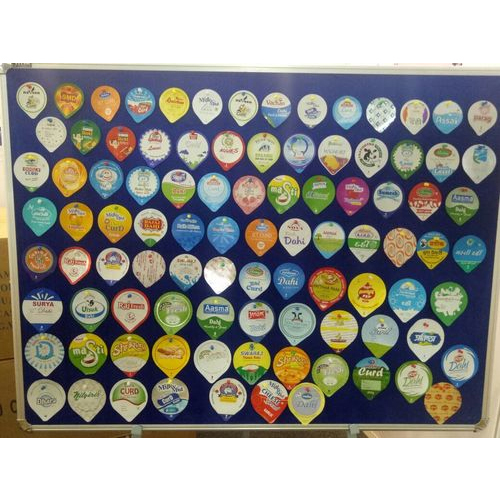

Dahi Cup Foil Lid, Curd Cup Foil Lid

Minimum Order Quantity : 100 Pieces

Type : Other, Foil Lid

Color : Multicolor

Product Type : Other, Dahi Cup Foil Lid, Curd Cup Foil Lid

Hardness : Soft

Dimension (L*W*H) : As per cup requirement

PVC Shrink Roll

Type : Other, Roll

Color : Clear

Product Type : Other, Shrink Roll

Hardness : Other, Flexible

Dimension (L*W*H) : Width: 100 mm to 800 mm | Length: upto 3000 m

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry