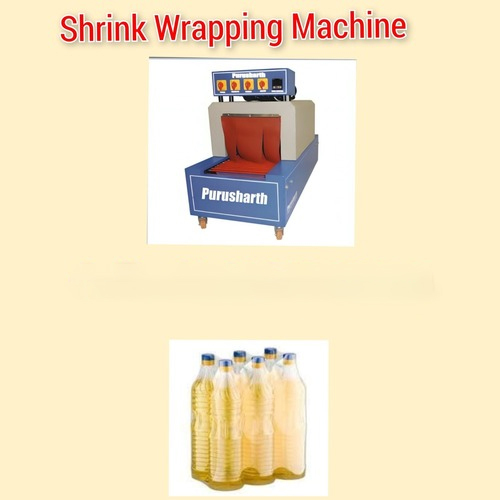

Shrink Tunnel Machine

Price 34500 INR/ Unit

MOQ : 1 Unit

Shrink Tunnel Machine Specification

- Type

- Shrink Tunnel Machine

- Material

- Mild Steel

- Capacity

- 800-1000 packages/hour

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Digital Temperature Controller

- Shrink Speed

- 0-10 m/min (adjustable)

- Air Pressure

- Not Required (uses heated air circulation)

- Roll Diameter

- Up to 250 mm

- Voltage

- 220V/380V

- Dimension (L*W*H)

- 1200 mm x 450 mm x 650 mm

- Weight

- Approx. 75-100 kg

- Color

- Gray & Orange

- Power Source

- Electric, Single/Three phase

- Noise Level

- Low

- Tunnel Entrance Size

- 400 mm (W) x 200 mm (H)

- Display

- Digital Display Panel

- Conveyor Type

- Roller/mesh conveyor

- Cooling System

- Fans for rapid cooling

- Installation

- Easy to install and operate

- Conveyor Speed

- Adjustable

- Heating Power

- 6-9 kW

- Application

- Shrink wrapping bottles, boxes, and other packages

- Applicable Film

- PVC, POF, Polyolefin

- Safety Features

- Overheating protection, Emergency stop

Shrink Tunnel Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- mundra

- Payment Terms

- Letter of Credit (L/C), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

About Shrink Tunnel Machine

Clients can avail from us an extensive array of Shrink Tunnel Machine. Designed and manufactured from high grade factor inputs and cutting edge technology as per the set industry norms, this wrapping machine assures longer working life. This Shrink Tunnel Machine is highly appreciated among clients for its corrosion resistance, perfect finish, sturdiness and extended durability. To meet the varied needs of clients, we offer this machine in different customized options at the most affordable prices.Efficient and Versatile Shrink Wrapping

Easily shrink wrap bottles, boxes, and more at speeds up to 1,000 packages per hour. This machine excels with its adjustable conveyor and compatibility with various shrink films, including PVC, POF, and Polyolefin. Its roller or mesh conveyor system ensures smooth package movement, while a digital temperature controller optimizes shrinking for different materials.

User-Friendly Digital Controls and Safety

Operate with confidence using a digital display panel and intuitive temperature controls. Built-in protections like overheating prevention and an emergency stop ensure operational safety. With easy installation and minimal training, any business can enhance its packaging process without hassle.

Durable Design for Industrial Applications

Constructed from mild steel and equipped with a robust cooling system, this machine delivers reliable performance for continuous high-volume operation. The low-noise, low-maintenance design maximizes productivity, making it suitable for manufacturers, exporters, and distributors looking for a reliable shrink packaging solution.

FAQs of Shrink Tunnel Machine:

Q: How does the shrink tunnel machine operate and what films can it process?

A: This shrink tunnel machine uses heated air circulation powered by a 6-9 kW heating element to shrink films like PVC, POF, and Polyolefin onto packages. Just load the package on the adjustable conveyor, set the desired speed and temperature via the digital display, and the machine handles the wrapping process efficiently.Q: What types of packages and industries can benefit from this shrink tunnel machine?

A: It is ideal for shrink wrapping bottles, boxes, and similar packages. Manufacturers, exporters, distributors, and suppliers dealing with packaged goodsespecially those in food, beverage, or retailbenefit from its capacity of 800-1000 packages per hour and the flexibility to accommodate various package sizes.Q: When should I use the roller conveyor versus the mesh conveyor?

A: The roller conveyor is best suited for rigid and stable items like bottles and sturdy boxes, while the mesh conveyor is recommended for smaller or lighter packages that may require extra support during transport through the tunnel. Selection depends on the product shape and weight.Q: Where can this machine be installed, and how easy is the installation process?

A: Designed for straightforward installation in factories, warehouses, or packaging units, this machine fits in spaces due to its compact size (1200 mm x 450 mm x 650 mm). Setup is user-friendly, requires no specialized knowledge, and the control panel guides operators through key functions.Q: What safety features are included during the shrink wrapping process?

A: Safety is prioritized with features like overheating protection and an easily accessible emergency stop button. These safeguards minimize risks associated with high temperatures and moving parts, ensuring secure operation in any industrial environment.Q: How do the cooling fans and digital temperature control enhance packaging quality?

A: After shrink wrapping, rapid cooling fans help solidify the film, yielding a tight, professional finish. The digital temperature controller ensures consistent heat application, reducing the likelihood of film damage and promoting uniform results across different package sizes and films.Q: What are the main benefits of using this machine for my business?

A: Key benefits include high-volume throughput, reliable shrink wrap quality, flexible film and package compatibility, user-friendly controls, low operating noise, and robust safety mechanisms. This boosts operational efficiency and enhances the professional appearance of your packaged products.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Shrink Wrapping Machine Category

Stretch Film Wrapping Machine

Price 338500 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Material : Mild Steel

Voltage : 220V / 50Hz

Shrink Wrapping Machine With Web Sealer

Price 230000.00 INR / Unit

Minimum Order Quantity : 1 Plant

Automatic Grade : SemiAutomatic

Material : MS powder coated

Voltage : 13.5 Volt (v)

Warranty : 1 year warranty

Oil Bottle Shrink Wrapping Machine

Price 34500 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic Grade : Automatic

Material : Stainless Steel

Voltage : 220V/380V Volt (v)

Warranty : 1 Year

Pharmaceutical Shrink Wrapping Machine

Price 88500 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Material : MS

Warranty : 1 Year

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry