Bearing packing machine

Price 198500 INR/ Unit

Bearing packing machine Specification

- Noise Level

- Low

- Usage

- Industrial bearing packaging

- Features

- Preserves product integrity double chamber functionality

- Power Supply

- Standard electrical supply

- Application

- Packaging bearings in vacuum seal

- Type

- Packaging machine

- Material

- Stainless steel

- Feature

- Vacuum sealing

- Auxiliary Packaging Machine Type

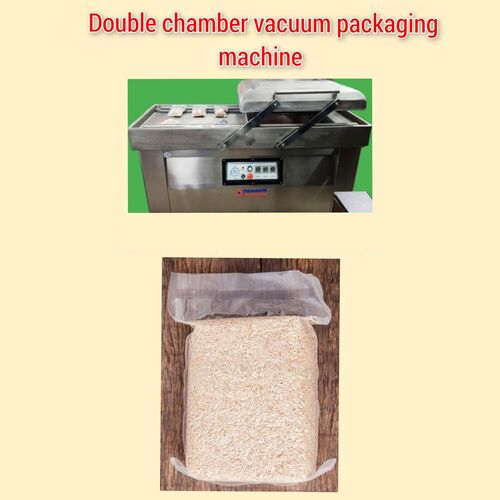

- Double chamber vacuum packaging machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Digital control panel

- Drive Type

- Electrical

- Color

- Stainless steel color

- Sealing Type

- Vacuum Sealing

About Bearing packing machine

VACUUM CHAMBER STAINLESS STEEL FLAT WORKING PLATE

SEALING LENGTH : 620 X 10 mm

CAPACITY 40 m 3/h

CYCLE TIME 10-40 sec.

VOLTAGE 3 PHASE 380 V/50 Hz

POWER 1.5 KW & 3.1 KW

MACHINE SIZE 1450 x 750 x 1000 mm

WORKROOM SIZE 670 x 540 x 110 mm

WEIGHT 320 KG

Efficient Double Chamber Design

This packaging machine features a double chamber vacuum system, allowing for continuous operation and higher productivity. The two chambers enable simultaneous preparation and sealing, reducing downtime and optimizing workflow in industrial bearing packaging applications.

Precision Digital Controls

Equipped with a computerized digital control panel, the bearing packing machine offers user-friendly operation and precise control over packaging parameters. This digital system ensures consistent vacuum pressure and sealing times, enhancing overall package quality and product protection.

FAQs of Bearing packing machine:

Q: How does the Bearing Packing Machine enhance the packaging process for bearings?

A: The Bearing Packing Machine uses a double chamber vacuum sealing system and automatic digital controls to efficiently package bearings, ensuring consistent vacuum seals and preserving the integrity of every bearing during distribution.Q: What materials are compatible with this packaging machine?

A: This model is specifically designed for packaging bearings but can accommodate other industrial products compatible with vacuum sealing and sized appropriately for the chamber.Q: When is it ideal to use a double chamber vacuum sealing machine for industrial packaging?

A: Double chamber vacuum sealing machines are most beneficial when large volumes of bearings need to be packaged rapidly and with minimal downtime, as the dual chambers facilitate a continuous and streamlined workflow.Q: Where can this machine be installed and operated for best results?

A: This vacuum packaging machine is best suited for industrial settings, such as manufacturing plants, distribution centers, or packaging facilitiesanywhere efficient and secure packaging of bearings is required.Q: What is the typical process for vacuum sealing bearings using this machine?

A: The operator places the bearings in packaging material within one chamber, initiates the vacuum and sealing cycle through the control panel, then repeats the process in the alternate chamber to maximize throughput.Q: How does the vacuum sealing feature benefit the packaged bearings?

A: Vacuum sealing protects bearings from dust, moisture, and oxidation during transport and storage, thereby maintaining their quality and extending shelf life.Q: What are the advantages of using a stainless steel construction for this machine?

A: Stainless steel construction offers durability, corrosion resistance, and hygiene, making it especially suitable for industrial environments where long-term reliability is essential.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VACUUM Packing Machine Category

rice vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Drive Type : Electric

Material : Stainless steel

Tea Packing Machine

Price 34500.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Automatic Grade : SemiAutomatic

Drive Type : Electric

Material : Mild Steel

Voltage : 220440 Volt (v)

Shrink Packing Machine

Price 48500.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Automatic Grade : SemiAutomatic

Drive Type : Electric

Material : Mild Steel

Voltage : 220440 Volt (v)

Corrugated Box Tapping Machine

Price 50000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Drive Type : Electric

Material : MS

Voltage : 110215 Volt (v)

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry