chana packing machine

Price 198500 INR/ Unit

chana packing machine Specification

- Power Supply

- Electricity

- Application

- Chana Packing

- Usage

- Food Packaging

- Features

- High Efficiency Double Chamber Design

- Noise Level

- Low

- Type

- Packaging Machine

- Material

- Stainless Steel

- Feature

- Vacuum Sealing for Long Shelf Life

- Auxiliary Packaging Machine Type

- Double Chamber Vacuum Packaging Machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Digital Controller

- Drive Type

- Vacuum Drive

- Color

- Silver

- Sealing Type

- Heat Sealing

About chana packing machine

VACUUM CHAMBER STAINLESS STEEL FLAT WORKING PLATE

SEALING LENGTH : 620 X 10 mm

CAPACITY 40 m 3/h

CYCLE TIME 10-40 sec.

VOLTAGE 3 PHASE 380 V/50 Hz

POWER 1.5 KW & 3.1 KW

MACHINE SIZE 1450 x 750 x 1000 mm

WORKROOM SIZE 670 x 540 x 110 mm

WEIGHT 320 KG

Double Chamber Vacuum Technology

The chana packing machine incorporates a double chamber vacuum system, enabling rapid and efficient packaging cycles. This design not only boosts productivity but also ensures higher throughput, making it suitable for large-scale food packaging businesses managing bulk quantities of chana.

Digital Precision and Automation

Equipped with a computerized digital controller, this packaging solution offers precise control over the vacuum and sealing process. The automatic grade functionality allows for hands-free operation, reducing labor costs and human error while maintaining packaging consistency and quality.

Stainless Steel Construction & Durability

Manufactured with high-grade stainless steel, this machine offers superior durability and hygiene. Its robust build ensures long-term reliability in demanding environments, while the sleek silver design provides easy cleaning and attractive appearance suitable for food processing units.

FAQs of chana packing machine:

Q: How does the double chamber design improve chana packaging efficiency?

A: The double chamber allows simultaneous loading and vacuum-sealing, minimizing downtime and increasing throughput. While one chamber is sealing, the other can be prepared for the next batch, streamlining operations and boosting packaging speed.Q: What is the process of vacuum sealing chana with this machine?

A: Chana is placed in packaging pouches, arranged in one of the machines chambers, and the lid is closed. The machine then automatically evacuates air, heat-seals the pouch, and releases the vacuum, preserving freshness and ensuring longer shelf life.Q: When should this machine be chosen over single chamber alternatives?

A: This double chamber vacuum packaging machine is recommended for medium to large-scale food processors or exporters needing higher speed, greater efficiency, and continuous operation, especially when dealing with significant quantities like bulk chana packaging.Q: Where is this chana packing machine typically used in India?

A: It is widely used in food processing factories, pulse and grain mills, distribution warehouses, and export-oriented packaging units across India, offering a reliable solution for safe and professional chana packaging.Q: What benefits does computerized digital control offer?

A: The digital controller ensures accurate programming of vacuum and sealing times, leading to consistent results, less manual intervention, and easy adjustments for different packaging requirements, enhancing product quality and operational efficiency.Q: How does the stainless steel build contribute to food safety?

A: Stainless steel construction is resistant to corrosion and easy to sanitize, ensuring compliance with food safety standards and minimizing the risk of contamination during the chana packaging process.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Packaging Machine Category

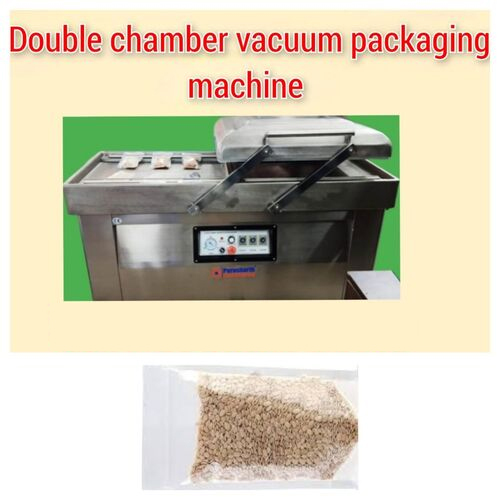

watermelon seeds vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Usage : Industrial packaging

Automatic Grade : Automatic

Material : Stainless steel

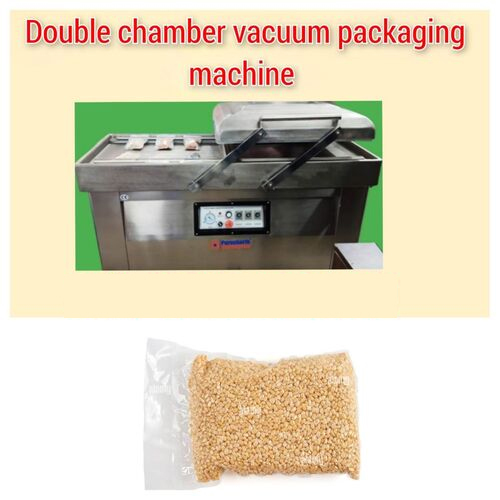

pine nut vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Usage : Packaging pine nuts and similar food items

Automatic Grade : SemiAutomatic

Material : Stainless steel body

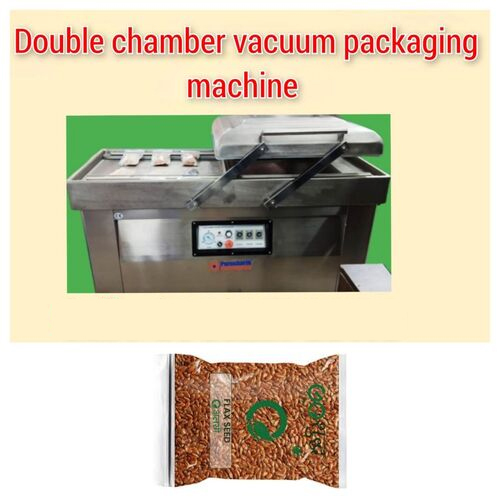

flax seeds vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Usage : Packing seeds like flax seeds

Automatic Grade : Automatic

Material : Stainless Steel

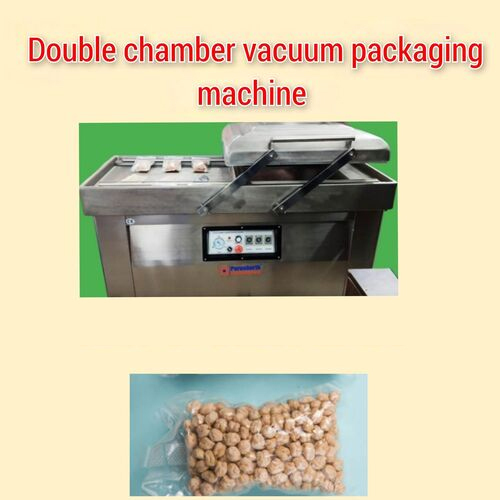

pumpkin seeds vacuum packing machine

Price 149999.0 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Usage : Packaging pumpkin seeds and similar dry/semidry items

Automatic Grade : Automatic

Material : Stainless steel

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry