handheld electromagnetic seling machine

Price 12800.00 INR/ Piece

handheld electromagnetic seling machine Specification

- Power Supply

- Electrics

- Type

- Capping Machines

- Material

- Mild Steel

- Automatic Grade

- Automatic

- Drive Type

- Manual

- Voltage

- 220 Volt (v)

- Weight (kg)

- Kilograms (kg)

- Dimension (L*W*H)

- Millimeter (mm)

- Color

- White

- Warranty

- 1 Year

handheld electromagnetic seling machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 5 Pieces Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Main Export Market(s)

- Middle East, Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Africa

- Main Domestic Market

- All India

About handheld electromagnetic seling machine

Click Here to Watch Video

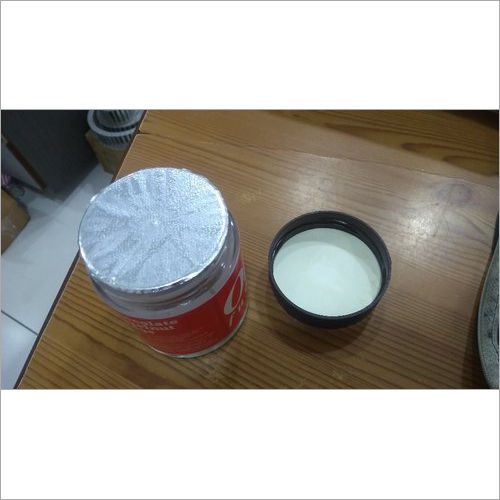

Overview: An induction sealing machine is designed to apply an electromagnetic seal to the closure of containers, typically made of plastic or glass. This process creates a hermetic seal that preserves the freshness, integrity, and safety of the product within.

Advanced Technology for Secure Sealing

Utilizing electromagnetic induction, this handheld capping machine delivers rapid and uniform sealing to ensure product safety. Its automatic operation streamlines workflow, minimizing errors while requiring only minimal manual effort. The units robust designfabricated from mild steel and fitted with secure wiringextends operational life and supports demanding production environments. Suitable for sealing containers in pharmaceutical, cosmetic, and food sectors, it meets rigorous packaging standards with ease.

Versatile Applications Across Industries

Designed for manufacturers, exporters, distributors, and suppliers, this machine adapts to various types of containers and caps, making it a versatile solution for a wide range of products. The 1-year warranty, combined with local support throughout India, ensures your investment is protected. Its efficient electrical drive supports continuous use in fast-paced environments, providing reliable sealing for both small-scale and high-volume production requirements.

FAQs of handheld electromagnetic seling machine:

Q: How does the handheld electromagnetic sealing machine work?

A: The machine uses electromagnetic induction to generate heat directly through the caps foil liner, bonding it securely to the containers mouth. The user holds the unit over the cap and initiates the sealing process; the machine then automatically completes the seal in a matter of seconds.Q: What types of containers can this capping machine be used with?

A: This device is suitable for plastic and glass bottles or jars with foil-sealed caps. It is commonly used in industries such as pharmaceuticals, food processing, and cosmetics for tamper-evident and leak-proof packaging.Q: When is the best time to use this machine in the packaging process?

A: The machine should be used after filling and capping the containers but before labeling and final packaging. It ensures that each unit is properly sealed, providing protection against leakage and contamination.Q: Where can I purchase or get support for this sealing machine in India?

A: This machine is available through multiple channels, including direct manufacturers, distributors, exporters, suppliers, and traders across India. Service support and warranty assistance can be accessed through your local distributor or the manufacturers customer service centers.Q: What is the process for operating the machine?

A: After connecting the machine to a 220-volt power supply, simply position the sealing head over the capped container and press the activation button. The automatic cycle will initiate the electromagnetic seal; when complete, the machine signals the end of the process.Q: How does using this machine benefit my production line?

A: The automated sealing process enhances speed, ensures consistent seal quality, and reduces labor requirements. Its manual drive allows flexibility for various container shapes and sizes, while the robust design ensures long-term performance, lowering maintenance costs and downtime.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Aluminium Seal Foils Category

Cup Foil Seal

Price 1 INR / Piece

Minimum Order Quantity : 1000 Pieces

Type : Other, Cup Foil Seal

Sealing Type : Heat Sealing

Computerized : Yes

Automatic Grade : Automatic

Foil Heat Induction Wad

Price 1 / Piece

Minimum Order Quantity : 30000 Pieces

Type : Other, Liner for container sealing

Sealing Type : Other, Heat induction

Computerized : Yes

Automatic Grade : Automatic

Heat Seal Wad

Price 1 INR / Piece

Minimum Order Quantity : 1 , , Piece

Type : Other, Heat Seal Wad

Sealing Type : Heat Seal, Other

Computerized : No

Automatic Grade : SemiAutomatic

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry