hardwer item packing machine(pneumatic blister machine)

hardwer item packing machine(pneumatic blister machine) Specification

- Type

- Blister Packaging Machines

- Feature

- Heavy Duty Machine

- Capacity

- Pcs/min

- Automatic Grade

- Semi-Automatic

- Power

- 1000 Watt (w)

- Voltage

- 220 Volt (v)

- Weight (kg)

- 105 Kilograms (kg)

- Dimension (L*W*H)

- Inch (in)

hardwer item packing machine(pneumatic blister machine) Trade Information

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID), Cheque, Letter of Credit at Sight (Sight L/C), Telegraphic Transfer (T/T)

- Supply Ability

- 2 Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Main Domestic Market

- All India

About hardwer item packing machine(pneumatic blister machine)

Pharmaceuticals:

- Blister Packs: Used for tablets, capsules, and oral medications, offering protection from moisture, light, and contamination.

- Compliance and Safety: Helps with patient adherence by providing a clear view of each dose and preventing tampering.

Consumer Goods:

- Electronics: Protects small electronic items from damage during transit and display, often used in retail environments.

- Household Items: Convenient for small items, ensuring product visibility and secure packaging.

Food and Beverages:

- Portion Control: Blister packs for snacks or single-serving items help manage portions and extend shelf life.

- Protection: Protects food items from contamination and spoilage while maintaining freshness.

Cosmetics and Personal Care:

- Product Samples: Ideal for single-use samples or small quantities, enhancing consumer trial and convenience.

- Travel-Friendly: Compact and secure packaging for personal care items.

Industrial Applications:

- Small Parts: Keeps mechanical or electronic parts organized, preventing loss and damage.

- Tools and Accessories: Provides a clear display and protection for various small tools and accessories.

Robust Construction for Demanding Applications

Engineered from premium materials, this heavy-duty pneumatic blister machine effortlessly handles extensive packing hours without compromising durability. The robust build enhances longevity, making it ideal for industrial packing environments that demand consistent results.

Efficient and Versatile Operation

Operating at 1000 Watts and 220 Volts, this semi-automatic blister packaging machine streamlines the packing process for hardware products. It accommodates variable packaging sizes while ensuring tight, tamper-proof seals to keep items protected.

Multiple Roles Served Across the Supply Chain

Designed for adaptability, this machine serves as a comprehensive solution for distributors, exporters, manufacturers, traders, service providers, and suppliers. Its flexibility and reliability make it a preferred choice for businesses throughout Indias packaging sector.

FAQs of hardwer item packing machine(pneumatic blister machine):

Q: How does the pneumatic blister packing machine enhance the packaging process for hardware items?

A: The pneumatic blister packing machine automates many steps of the packaging process, reducing manual labor and mitigating errors. It ensures consistent sealing, resulting in securely packed hardware that is protected against dust, moisture, and handling damage.Q: What are the primary benefits of using a heavy-duty blister packaging machine?

A: The heavy-duty construction allows for high-capacity operations, improved durability, and minimal maintenance. This leads to greater efficiency, reduced downtime, and a more reliable packaging process, particularly for businesses handling bulk quantities.Q: When should a business consider investing in a semi-automatic blister machine?

A: Businesses should consider a semi-automatic blister machine when their packaging volume exceeds what can be efficiently handled manually, but full automation is not yet required. Its ideal for mid- to large-scale operations seeking improved productivity and consistency.Q: Where can the pneumatic blister packing machine be effectively utilized?

A: This blister machine is ideal for use in hardware manufacturing units, distribution centers, export facilities, and trading houses throughout India. Its adaptability also enables use in service centers requiring secure and presentable product packaging.Q: What is the process for packaging hardware items with this machine?

A: The process typically involves placing the hardware item into the pre-formed blister, positioning the blister onto the sealing platform, and operating the machine to heat-seal the blister to a backing card using pneumatic pressure for a durable, tamper-evident package.Q: How does the power and voltage specification benefit the user?

A: With a 1000 Watt power capacity and 220 Volt requirement, the machine achieves efficient heating and sealing, shortening cycle times while maintaining energy efficiency. This ensures optimal performance even in high-demand scenarios.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BLISTER PACKING MACHINE Category

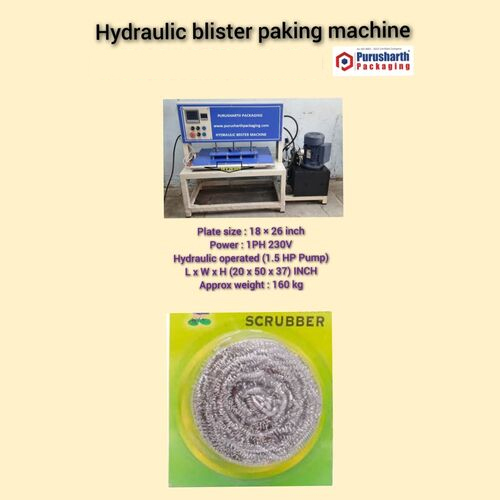

Stainless steel scrubber packing machine

Price 98500.0 INR / Unit

Minimum Order Quantity : 1 Piece

Power : 1500W Watt (w)

Drive Type : Hydraulic

Automatic Grade : SemiAutomatic

Feature : Other

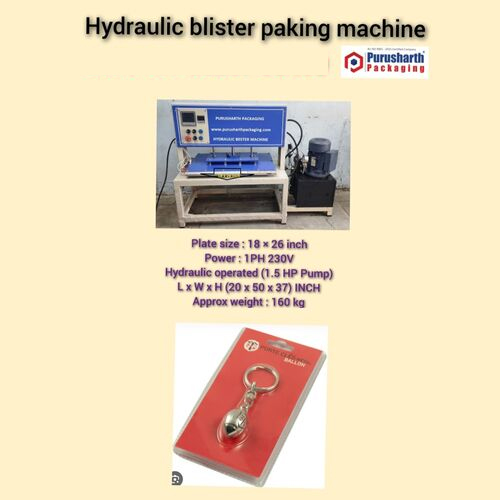

keychain packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 1 Unit

Power : 1 Phase 220V

Drive Type : Other, Hydraulicoperated (0.5 HP Pump)

Automatic Grade : SemiAutomatic

Feature : Other, Hydraulic blister packing machine designed for packaging keychains

Earphone packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 01 Unit

Power : 1PH 230V

Drive Type : Hydraulic

Automatic Grade : Hydraulic operated, Other

Feature : Other, Efficient hydraulic operations

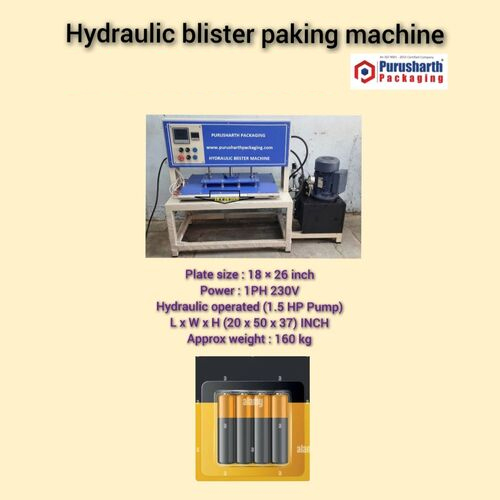

Battery cell packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 01 Unit

Power : 1 HP

Drive Type : Hydraulic

Automatic Grade : SemiAutomatic

Feature : Other, Efficient battery cell packaging

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry