Heat Sealing Machine

Price 1500 INR/ Unit

Heat Sealing Machine Specification

- Voltage

- 220V / 50Hz

- Type

- Heat Sealing Machine

- Sealing Length

- Customized (Standard: 10-600 mm)

- Sealing Speed

- 0-12 m/min

- Weight

- Approx. 25 Kg

- Automation Grade

- Automatic

- Accuracy

- High

- Contact Load

- 10A

- Power

- 500W

- Condition

- New

- Dimension (L*W*H)

- 620 mm x 150 mm x 210 mm

- Color

- Green

- Packaging Material

- Plastic, Laminated Film, Aluminium Foil

- Driven Type

- Electric

- Application

- Plastic Bag, Pouches, Laminated Bags, Foil Sealing

- Sealing Type

- Horizontal Continuous

- Filling Capacity

- Up to 1 Kg bags

- Packaging Speed

- 8-15 bags/min

- Seals Type

- Flat / Grooved / Customized

- Production Capacity

- Up to 900 bags/hour

- Noise Level

- < 65 dB

- Body Material

- Mild Steel (Powder Coated)

- Temperature Range

- 0°C to 300°C Adjustable

- Cooling System

- Integrated Fan

- Max Seal Width

- 10 mm

- Conveyor Width

- 140 mm

- Control Panel

- Digital Temperature Controller

- Operation Mode

- Continuous / Intermittent

- Ideal For

- Food, Pharma, Chemical, Agriculture Packaging

- Safety Features

- Overheat Protection, Emergency Stop

Heat Sealing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 5 Units Per Day

- Delivery Time

- 5 Days

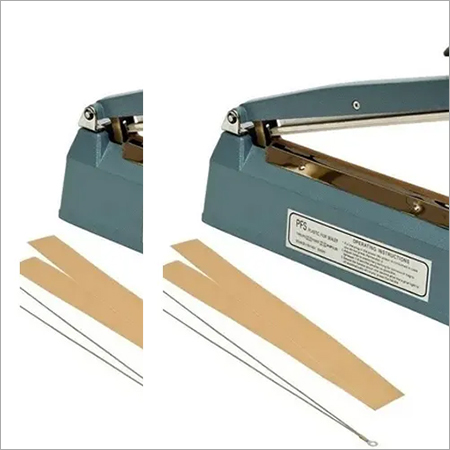

About Heat Sealing Machine

Heat Sealing Machine- Ready to use instantly No warm up needed

- The operation of the machine is very easy. Just put a plastic bag on the sealing platform , and then push down the handle . After 1-2 second, release the handle The perfect seal is complete.

- Adjustable timer allows perfect seals for a wide variety of bags thickness

- This sealing machine includes the feature of timer knob .You can increase or decrease the heat time using timer knob to avoid any break, damage or non-tighten seal.

- Technical Support Available. Different material bag need different temperature setting.

Advanced Temperature Control

The heat sealing machine features a digital temperature controller that allows precise adjustment from 0C to 300C. This flexibility ensures seam integrity for various packaging materials such as plastic, laminated films, and aluminum foils, reducing the risk of burning or under-sealing.

Versatile Sealing Capabilities

Customize sealing length from 10 mm up to 600 mm to accommodate different bag and pouch sizes. With a conveyor width of 140 mm and support for flat, grooved, or tailored seals, this machine efficiently processes bags up to 1 kg in both continuous and intermittent modes.

Built-in Safety and Efficiency

Integrated features such as an overheat protection system, emergency stop button, and fan-based cooling make operations safer and more reliable. The machine delivers a high packaging speed of 8-15 bags per minute, optimizing productivity for busy packaging environments.

FAQs of Heat Sealing Machine:

Q: How does the digital temperature controller improve the sealing process?

A: The digital temperature controller allows precise adjustments within the 0C to 300C range, enabling optimal seal quality based on the packaging material. This accuracy prevents overheating or under-sealing, ensuring consistent and reliable results.Q: What types of packaging materials can this machine seal?

A: This heat sealing machine is suitable for sealing plastic bags, laminated films, aluminum foils, and a variety of pouches, making it ideal for diverse applications in food, pharmaceutical, chemical, and agriculture industries.Q: When is it recommended to use the continuous operation mode?

A: Continuous operation mode is ideal for high-volume production where a steady flow of bags or pouches must be sealed quickly and consistently, such as in automated production lines for food or chemical packaging.Q: Where can this machine be integrated within a packaging facility?

A: Thanks to its compact dimensions (620 x 150 x 210 mm) and moderate weight, this machine can be positioned either on a standalone table or as part of an automated conveyor system in packaging lines, maximizing workspace flexibility.Q: What is the process for adjusting bag sealing sizes and types?

A: Sealing length is customizable (standard 10-600 mm), and the machine supports flat, grooved, or user-specified seal types. Adjust settings on the control panel to match pouch dimensions and select the required seal profile for each product batch.Q: How does the integrated cooling and safety system benefit the operator?

A: An integrated fan cools seals immediately after heat application, preventing deformation and boosting throughput. Safety features like overheat protection and emergency stop button enhance operator safety during busy runs.Q: What are the main benefits of using this heat sealing machine?

A: Major advantages include reliable, high-speed sealing (up to 900 bags/hour), compatibility with various packaging materials, enhanced safety, precise temperature control, and customizable sealing options, all contributing to improved productivity and product quality.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Sealing Machine Category

Auto Induction Cap Sealer With Conveyor

Price 98500.0 INR / Piece

Minimum Order Quantity : 1 Piece

Condition : New

Application : Cap sealing for bottles Chocolate Jar Sealing Pickle Jar Sealing Honey Jar Sealing

Type : Cap Sealer

Voltage : 220V Volt (v)

Foot Operated Sealing Machine

Price 13500.00 INR / Unit

Minimum Order Quantity : 1 Piece

Condition : New

Application : Packaging Sealing

Type : Sealing Machines

Voltage : 220440 Volt (v)

L Type Sealing Machine

Price 34500 INR / Unit

Minimum Order Quantity : 1 Unit

Condition : New

Type : L Type Sealing Machine

Voltage : 110215 Volt (v)

Band Sealer

Minimum Order Quantity : 1 Unit

Condition : New

Application : For Mehndi Pouch Sealing Besan Pouch Sealing Flour Pouch Sealing Rice Powder Pouch Sealing Powder, BioFertilizers Packing Pesticides Powder Packing Spices Powder Packing Machine

Type : automatic

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry