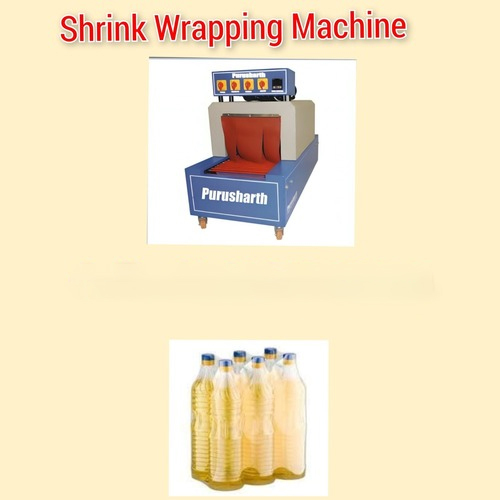

Oil Bottle Shrink Wrapping Machine

Price 34500 INR/ Unit

Oil Bottle Shrink Wrapping Machine Specification

- Type

- Shrink Wrapping Machine

- Material

- Stainless Steel

- Capacity

- Up to 600 bottles/hour Pcs/hr

- Computerized

- Yes

- Automatic Grade

- Automatic

- Roll Diameter

- 300 mm Millimeter (mm)

- Voltage

- 220V/380V Volt (v)

- Dimension (L*W*H)

- 2000 x 800 x 1500 mm Millimeter (mm)

- Weight

- 150 Kg Kilograms (kg)

- Color

- Blue and Orange

- Warranty

- 1 Year

About Oil Bottle Shrink Wrapping Machine

An Oil Bottle Shrink Wrapping Machine is designed to apply shrink film around oil bottles for tamper-proof packaging and secure sealing. Key components include the film dispenser, heat tunnel, sealing system, and conveyor belt. Common models vary in capacity and size, with automatic or semi-automatic types available. Constructed from stainless steel, the machine ensures durability and hygiene. It functions by wrapping the bottle with heat-sensitive film and using a heat tunnel for shrinkage. Used widely in food and beverage, pharmaceutical, and cosmetics industries, it ensures efficient, high-speed packaging with consistent performance and minimal downtime. Key specifications include adjustable temperature controls, speed settings, and precision wrapping.

Efficient Bottle Packaging

Designed for high-volume oil bottle packaging, this shrink wrapping machine operates automatically and can process up to 600 bottles per hour, making it ideal for industrial applications. Its computerized system ensures precision and consistency with minimal manual intervention.

Solid Build and Vibrant Design

Constructed from high-grade stainless steel, the machine delivers robust performance and longevity. The blue and orange color scheme enhances visibility and modernizes your workspace, while its compact dimensions facilitate easy installation.

Optimized for Indian Industry Needs

With multiple roles including distributor, exporter, manufacturer, service provider, supplier, and trader, this machine brings flexibility and efficiency to businesses across India. The warranty and after-sales service promise reliable support for smooth operations.

FAQs of Oil Bottle Shrink Wrapping Machine:

Q: How does the Oil Bottle Shrink Wrapping Machine operate automatically?

A: The machine uses computerized controls to automate the shrink wrapping process, allowing bottles to be fed into the system and wrapped quickly without manual intervention. This greatly increases efficiency and reduces the risk of errors.Q: What types of oil bottles can be wrapped with this machine?

A: The shrink wrapping machine is suitable for a variety of oil bottles that fit within its operational capacity and dimensions. It can accommodate most standard sizes, ensuring the bottles are securely wrapped for transport and storage.Q: When is maintenance required for the shrink wrapping machine?

A: Routine maintenance is recommended every few months, depending on usage volume. The machine comes with a one-year warranty, and service providers in India are readily available to support maintenance and troubleshooting needs.Q: Where can this machine be installed within an industrial facility?

A: Due to its compact size (2000 x 800 x 1500 mm), the machine can be installed in standard production areas, packaging departments, or dedicated wrapping zones within a facility without taking up excessive space.Q: What is the process for shrink wrapping oil bottles with this equipment?

A: Bottles are placed on the conveyor, where the machine applies shrink film from its 300 mm roll. Heat is applied automatically, causing the film to tightly conform to the bottles, which are then ready for packing and shipping.Q: How does this machine benefit distributors and manufacturers?

A: The automated system enables rapid, uniform bottle wrapping, minimizing labor costs and maximizing throughput. Its high hourly capacity and reliable performance help distributors and manufacturers meet large orders efficiently.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shrink Wrapping Machine Category

Stretch Film Wrapping Machine

Price 338500 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 220V / 50Hz

Material : Mild Steel

Control System : PLC Control

Automatic Grade : SemiAutomatic

A4 Paper Box Shrink Wrapping Machine

Price 34500 INR / Unit

Minimum Order Quantity : 01 Unit

Voltage : 220V/50Hz

Material : Stainless Steel

Control System : Other, PLC Control System

Automatic Grade : SemiAutomatic

Automatic shrink machine

Price 34500 INR / Unit

Minimum Order Quantity : 1 , , Unit

Voltage : 220415 Volt (v)

Material : Mild Steel

Automatic Grade : SemiAutomatic

Semi Automatic Shrink Wrap Machine

Price 27000 INR / Unit

Minimum Order Quantity : 1 Unit

Voltage : 240 Volt (v)

Material : MS

Control System : Human Machine Interface

Automatic Grade : SemiAutomatic

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry