Rusk Packing Machine

Price 34500 INR/ Unit

Rusk Packing Machine Specification

- Application

- Automatic packing of rusk in food processing industry

- Usage

- Food packaging

- Noise Level

- Low

- Features

- Stainless steel contact parts, user-friendly touch panel, adjustable pack length, high accuracy

- Power Supply

- AC

- Filling Range

- Variable as per customer specification

- Type

- Rusk Packing Machine

- Material

- Stainless Steel

- Feature

- Corrosion resistant, high speed, precise packing, low maintenance

- Auxiliary Packaging Machine Type

- Automatic Wrapping Machine

- Capacity

- 30-80 packs/min (depending on product and pack size)

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- PLC based Human-Machine Interface (HMI)

- Drive Type

- Electric motor driven

- Power

- 2.5 kW

- Voltage

- 220V / 50Hz (Single Phase)

- Weight (kg)

- Approx. 750 kg

- Dimension (L*W*H)

- 4100 mm x 970 mm x 1400 mm

- Color

- Silver

- Sealing Type

- Heat Sealing

Rusk Packing Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- FOB Port

- mundra

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 1 Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia, Africa

About Rusk Packing Machine

Rusk Packing Machine

Facilitated by technically advanced process, we are manufacturing and exporting an excellent quality range of Continuous Sealer. Sturdy in construction and safe to operate, this is used for packaging of spices, namkeen, chemicals, medicine and dairy products. We manufacture this at our technically sound production unit using optimum grade materials and highly advanced technology. Our quality inspectors test this Horizontal Continuous Bag Sealer on diverse parameters before dispatching at clients end.

CLICK TO WATCH PACKING MACHINE VIDEO

Technical Specifications

|

Minimum Order Quantity |

1 Unit |

|

Capacity |

As Per Company Standard |

|

Brand |

PURUSHARTH |

|

Model |

HDCBSM |

High-Speed, Accurate Rusk Packing

This rusk packing machine efficiently packs 3080 rusks per minute, offering adjustable conveyor speed and pack sizes for flexible production needs. Its precision and consistency minimize errors and wastage, making it ideal for large- and medium-scale food operations.

Advanced User Control and Safety Features

Operational control is simplified by a PLC-based Human-Machine Interface (HMI) and a user-friendly digital LCD panel. Key safety elements such as emergency stops, overload protection, and safety guards ensure secure use in busy factories, enhancing operator confidence and reducing downtime.

Versatile Film Compatibility

Suitable for BOPP, laminated films, and various food-grade packaging materials, the machine delivers reliable sealing performance. This versatility allows manufacturers to select the best packaging option for their product and market needs, while maintaining food safety standards.

FAQs of Rusk Packing Machine:

Q: How does the quick changeover mechanism work on the Rusk Packing Machine?

A: The machine features a quick changeover mechanism that allows operators to easily adjust pack lengths, widths, and heights within the specified range. This reduces downtime between production runs and ensures rapid adaptation to different rusk sizes, maximizing productivity.Q: What types of packaging materials are compatible with this machine?

A: This automatic wrapping machine supports BOPP films, laminated films, and other food-grade packaging materials. Its heat sealing mechanism ensures secure packaging, providing versatility for various market requirements.Q: What safety features are integrated into the Rusk Packing Machine?

A: For operator protection, the machine is equipped with an emergency stop button, overload protection system, safety guards, and a low-noise design. These features work together to create a safe work environment in food manufacturing settings.Q: When and where is the Rusk Packing Machine commonly used?

A: The machine is typically utilized in food processing environments, including factories, packaging plants, and production lines involved in rusk manufacturing and distribution. Its automation and speed make it suitable for continuous, high-volume operations.Q: What are the main benefits of using this automated rusk packing machine?

A: Users benefit from high packing speeds, precise and consistent packaging, low maintenance requirements, user-friendly controls, and reliable corrosion-resistant construction, all of which contribute to increased operational efficiency and product quality.Q: How does the machine handle different product and pack sizes?

A: Operators can adjust the pack size settings via the intuitive touch panel, allowing the machine to accommodate varying lengths (60300 mm), widths (3090 mm), and heights (1060 mm), making it suitable for different rusk shapes and sizes.Q: What kind of after sales service and support is offered with this machine?

A: Comprehensive after sales service includes installation, training, and technical support. This ensures that operators are properly trained for optimal machine use and efficiency, and helps clients quickly resolve any operational issues.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VACUUM Packing Machine Category

Strapping Patti Packing Machine

Price 34500 INR / Unit

Minimum Order Quantity : 1 , , Unit

Usage : Strapping and sealing packages

Material : Steel and Plastic

Automatic Grade : SemiAutomatic

Color : Other, Blue and White

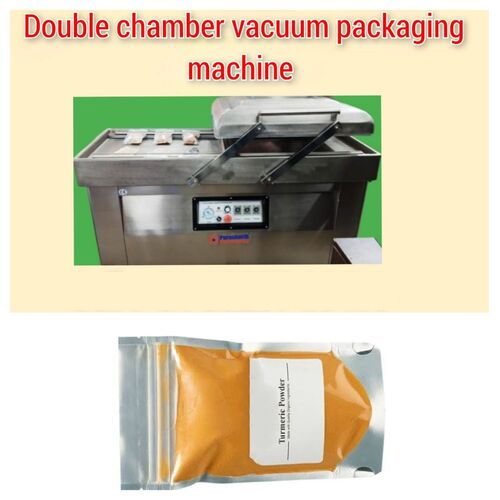

turmeric powder vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Food packaging especially spices and powders

Material : Stainless steel

Automatic Grade : Automatic

Color : Silver

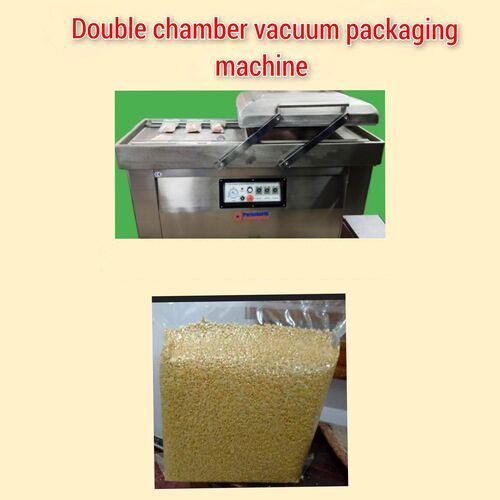

Double Chamber Vacuum Packaging Machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1

Usage : Industrial Packaging

Material : Stainless Steel

Automatic Grade : SemiAutomatic

Color : Other

dal packing machine

Price 198500 INR / Unit

Minimum Order Quantity : 01 Unit

Usage : Packaging Dal efficiently in airtight bags

Material : Stainless Steel

Automatic Grade : Automatic

Color : Silver

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry