Date Coding Ribbon Code Expire Date Batch Coding Machine for Plastic and Aluminium Foil Bags

MOQ : 1 Unit

Date Coding Ribbon Code Expire Date Batch Coding Machine for Plastic and Aluminium Foil Bags Specification

- Type

- Batch coding machine

- Material

- Plastic and aluminium foil bags

- Capacity

- Suitable for small to medium-scale operations

- Printing Speed

- Variable user-defined

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Plate Type

- Customizable embossing plate

- Print Direction

- Horizontal and vertical

- Ink Type

- Date coding ribbon

- Color Management

- Standard color management

- Control System

- Manual control buttons

- Working Temperature

- Standard room temperature

- Power

- Electric 1.5m cord length

- Size

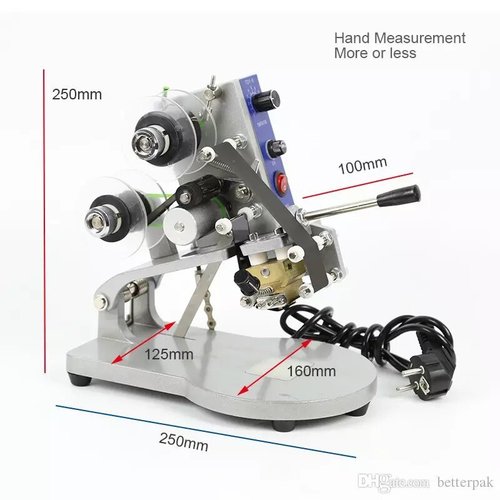

- Compact tabletop design

- Width

- 80mm ribbon width

- Weight (kg)

- Approx. 3.5 kg

- Dimension (L*W*H)

- 240mm x 140mm x 240mm

- Warranty

- 1 Year

About Date Coding Ribbon Code Expire Date Batch Coding Machine for Plastic and Aluminium Foil Bags

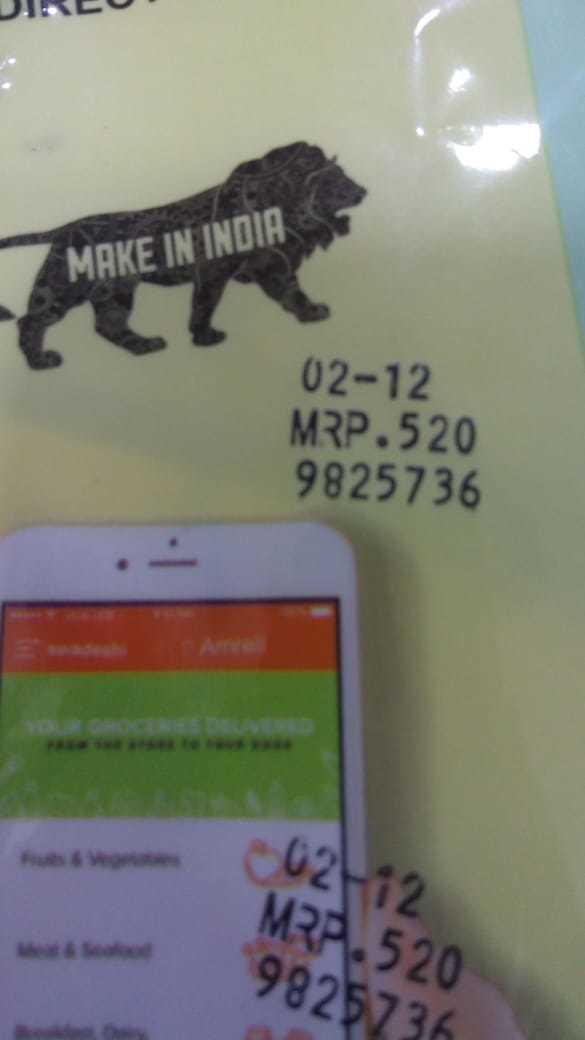

- Adopt color ribbon, has the features of clear printing , easy dry, nono sticky, not easy to wipe to wipe off.

- Can print codes on thin paper carboard, paper sheet, leather plastic film, aluminum foil, especially fit for coding on paper box of shoes, clothing.

- Adopt constant temperature controlling and adjustable temperature, printed suitable for color ribbon made out of different kinds of materials.

- It can automatic continuously print codes or control by handle.

Efficient Marking for Your Packaging Needs

Designed with a compact footprint, this batch coding machine allows businesses to efficiently print date codes, batch numbers, and expiration details on plastic or aluminium foil packs. The manual button control ensures intuitive operation, while customizable print plates and variable speeds offer flexibility for different products. This versatile solution supports both horizontal and vertical printing to match your packaging designs.

Reliable and User-Friendly Operation

The semi-automatic design streamlines your coding process with minimal training required. Its electric-powered operation and manageable weight (about 3.5 kg) make it easy to move and integrate into various production spaces. With standard color management and a 1-year warranty, users can be confident in consistent performance and dependable service over time.

FAQs of Date Coding Ribbon Code Expire Date Batch Coding Machine for Plastic and Aluminium Foil Bags:

Q: How do I operate the Date Coding Ribbon Code Expire Date Batch Coding Machine?

A: The machine operates using manual control buttons, enabling straightforward setup and operation. Simply install your embossing plate, thread the ribbon, adjust print direction and speed as needed, and press the button to print codes on each bag.Q: What types of packaging materials are compatible with this batch coding machine?

A: It is specifically designed for use with plastic and aluminium foil bags, making it suitable for food, pharmaceuticals, and various consumer goods that require precise date or batch coding.Q: When should I use a batch coding machine like this in my production process?

A: This machine is best used post-filling and sealing, just before final packaging, to ensure accurate batch and expiry details are marked on each product for traceability and compliance.Q: Where can this coding machine be placed in my facility?

A: With its compact tabletop design and 3.5 kg weight, the machine can be easily positioned on any stable work surface near your production line for convenient access and operation.Q: What is the process for customizing the embossing plate for different codes?

A: Embossing plates can be customized by replacing the type block or numbers to reflect varying batch codes or expiry dates, allowing flexibility for different products or production runs.Q: How does using this batch coder benefit my business?

A: Utilizing this batch coding machine streamlines your product labeling, improves traceability, and ensures regulatory compliance, ultimately enhancing product credibility and overall operational efficiency.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in MRP and Batch Printing Machine Category

Date Coding Ribbon Code Expire Date Batch Coding Machine For Plastic And Aluminium Foil Bags

Minimum Order Quantity : 1 , , Piece

Type : Batch Coding Machine

Automatic Grade : SemiAutomatic

Computerized : No

Material : SS

Table Top Batch Coding Machine

Price 7500 INR / Unit

Minimum Order Quantity : 1 , , Unit

Type : Table Top Batch Coding Machine

Automatic Grade : SemiAutomatic

Computerized : No

Material : Stainless Steel

Batch Printing Machinery

Price 230000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Inkjet Printing Machine

Automatic Grade : SemiAutomatic

Computerized : Yes

Material : SS

Hot Foil Ribbon Coding Machine

Price 7500 INR / Unit

Minimum Order Quantity : 1 Unit

Type : Hot Foil Ribbon Coding Machine

Automatic Grade : SemiAutomatic

Computerized : No

Material : Mild Steel

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry