Hot Foil Ribbon Coding Machine

Price 7500 INR/ Unit

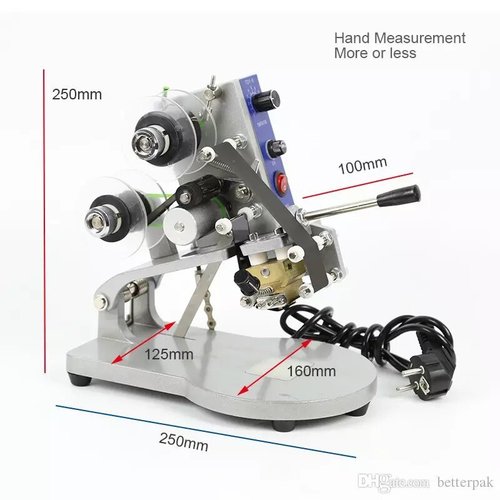

Hot Foil Ribbon Coding Machine Specification

- Type

- Hot Foil Ribbon Coding Machine

- Material

- Mild Steel

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Size

- Standard

- Warranty

- 1 Year

Hot Foil Ribbon Coding Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 10 Units Per Week

- Delivery Time

- 7 Days

About Hot Foil Ribbon Coding Machine

Hot Foil Ribbon Coding Machine

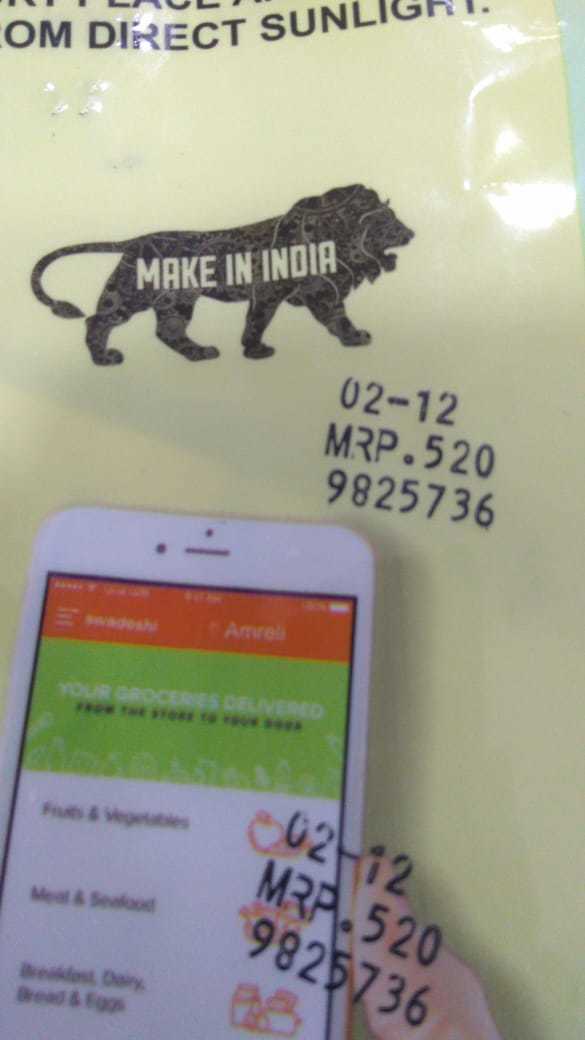

Hot Foil Ribbon Coding Machine , widely used in food, beverage, pharmaceutical and other industries printing production date, batch number, weight and so on. The aircraft introduced in Japan hot coding technology, using thermal printing ribbon instead of ink printing in a variety of flexible packaging material (except metal material) printed on a clear character, the aircraft hit the code clear and indelible, the volume small, light weight, easy to operate, simple to use, easy maintenance, hygienic printing is an economical way.

Product features of coding machine for reference:

- Using thermal printing ribbon to avoid oil contamination worries, to ensure that products, hand and mechanical hygiene and clean. Especially for food, pharmaceutical and other industries.

- Automatic continuous printing, you can also control the foot switch. Rational design, precision machining, high-quality quality assured to make users easy maintenance.

- Unique word structure, convenient to take special handling for word structure, flexible packaging materials in any code.

- Thermostatic control, temperature adjustable for different materials and ribbons. Print writing clear, instant printing and instant dry, strong adhesion, clean non stick.

- Can be widely used for paper, cardboard, leather, plastic film, shrink film, aluminum foil and other materials on print production date, batch number, date of manufacture, origin, weight, price, size, composition, distributors and manufacturers.

Robust Construction for Everyday Use

Constructed from mild steel, this coding machine guarantees durability for regular industrial operation. Its semi-automatic design bridges efficiency and hands-on control, which makes it an excellent choice for small to medium scale enterprises. The machines standardized dimensions ensure compatibility with various production lines, adding versatility to your packaging process.

Effortless Hot Foil Coding

The semi-automatic hot foil ribbon coding machine employs thermal transfer to imprint codes, dates, or batch numbers onto packaging. Free from computerized interfaces, it is both user-friendly and dependable. The hot foil ribbons used in this technique provide clear, smudge-resistant markings that wont deteriorate over time, meeting strict packaging requirements.

FAQs of Hot Foil Ribbon Coding Machine:

Q: How does the Hot Foil Ribbon Coding Machine work?

A: The machine uses heat and pressure to transfer pigment from a hot foil ribbon onto packaging materials. By placing the ribbon and packaging material in the machine and operating the semi-automatic controls, users can imprint clear codes or batch numbers with each cycle.Q: What materials are suitable for coding with this machine?

A: This coding machine is ideal for various non-porous packaging materials like plastic films, laminated foils, papers, and cartons. Its hot foil technology ensures excellent adhesion and visibility on these surfaces.Q: When should maintenance be performed on the machine?

A: Routine maintenance should be conducted every few weeks, including cleaning of the coding head and checking mechanical components for wear. Adhering to the recommended maintenance schedule helps sustain performance and extends the equipments service life.Q: Where can this machine be purchased or serviced in India?

A: The Hot Foil Ribbon Coding Machine is widely available throughout India via recognized distributors, exporters, manufacturers, service providers, suppliers, and traders. Service and support are also provided by these entities for ongoing operational needs.Q: What is the process for coding packages with this machine?

A: To code packages, load the ribbon, adjust the temperature and print position, place your packaging item, and operate the lever or switch. The machine then presses the heated die onto the ribbon and packaging, imprinting the required information.Q: How does using this machine benefit my packaging operation?

A: By implementing this machine, businesses achieve fast, accurate, and permanent coding of products. It enhances traceability, complies with labeling regulations, and reduces manual errors compared to hand-stamping methods.Q: Is this machine computerized, and does it require special skills to operate?

A: This model is not computerized and is designed for simple semi-automatic operation. Basic training on standard controls is sufficient, making it accessible for most operators without advanced technical background.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in MRP and Batch Printing Machine Category

Date Coding Ribbon Code Expire Date Batch Coding Machine For Plastic And Aluminium Foil Bags

Minimum Order Quantity : 1 , , Piece

Automatic Grade : SemiAutomatic

Computerized : No

Type : Batch Coding Machine

Material : SS

Table Top Batch Coding Machine

Price 7500 INR / Unit

Minimum Order Quantity : 1 , , Unit

Automatic Grade : SemiAutomatic

Computerized : No

Type : Table Top Batch Coding Machine

Material : Stainless Steel

Date Coding Ribbon Code Expire Date Batch Coding Machine for Plastic and Aluminium Foil Bags

Price 6000 INR

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Computerized : No

Type : Batch coding machine

Material : Plastic and aluminium foil bags

Batch Printing Machinery

Price 230000.00 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Computerized : Yes

Type : Inkjet Printing Machine

Material : SS

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry