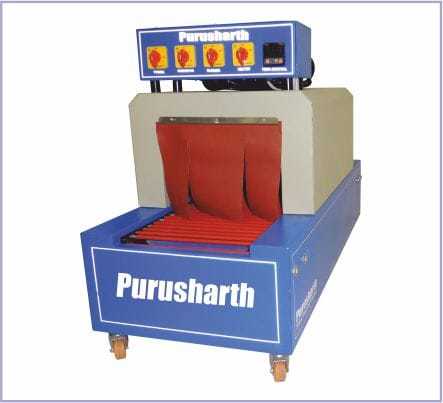

Food Shrink Wrap Machine

Price 44500 INR/ Unit

Food Shrink Wrap Machine Specification

- Type

- Food Shrink Wrap Machine

- Material

- Stainless Steel

- Capacity

- 800-1000 Packs/Hour

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Control System

- Manual Control Panel

- Shrink Speed

- Adjustable

- Roll Diameter

- Max 300 mm

- Voltage

- 220V

- Dimension (L*W*H)

- 1150 x 600 x 750 mm

- Weight

- 85 kg

- Color

- Silver

- Sealing Type

- Manual Impulse Sealing

- Safety Features

- Overheat Protection

- Chamber Type

- Open Structure

- Film Compatibility

- PVC, Polyolefin, POF films

- Mobility

- Portable, Countertop model

- Usage

- Food Packaging, Bakery, Retail

- Heating Method

- Electric Heating Element

- Power Consumption

- 1.2 kW

- After-Sales Service

- Available

- Operating Temperature Range

- 120-200°C

- Max Packing Size

- 450 x 300 mm

Food Shrink Wrap Machine Trade Information

- Minimum Order Quantity

- 1 , , Unit

- FOB Port

- mundra

- Payment Terms

- Telegraphic Transfer (T/T), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 10 Units Per Week

- Delivery Time

- Days

- Sample Available

- Yes

- Sample Policy

- Contact us for information regarding our sample policy

- Main Export Market(s)

- Asia

About Food Shrink Wrap Machine

we are offering Food Shrink Wrap Machine, which is fabricated using high grade raw materials as per the set industry norms. This is widely acknowledged among clients for its sturdy construction, high durability, corrosion resistance and longer service life. We offer this Food Shrink Wrap Machine in diverse specifications as per the varied demands of our precious customers. In order to offer a defect free range at the clients end, this machine is stringently tested on various quality parameters.

Product Details

|

Minimum Order Quantity |

1 Unit |

|

AutomatIc Grade |

Automatic |

|

Brand |

purusharth |

|

Usage |

Industrial |

Versatile Food Packaging Solution

The Food Shrink Wrap Machine is engineered for rapid and flexible packaging operations. Its compatibility with various shrink films and adjustable speed allows seamless adaptation to different food products, whether for bakery, retail, or broader food industry applications. The open chamber structure accommodates items of varying dimensions, ensuring consistently professional packaging results for every use.

User-Friendly and Portable Design

With a compact, countertop structure and weighing just 85 kg, this machine can be easily moved and positioned, making it suitable for spaces with limited room. The manual impulse sealing system paired with a straightforward control panel gives operators clear, intuitive command over the packing process, streamlining daily workflows without complex setup or technical knowledge.

Durable Construction and Safety Assured

Crafted from high-grade stainless steel, the machine is built for long-lasting performance and easy maintenance. Overheat protection enhances operational safety during extended use, while the efficient electric heating element ensures fast, reliable, and uniform shrink wrapping. Supported by available after-sales service, users benefit from long-term reliability and peace of mind.

FAQs of Food Shrink Wrap Machine:

Q: How does the manual impulse sealing system work on this shrink wrap machine?

A: The manual impulse sealing system requires the operator to initiate the sealing process by manually lowering the sealing bar onto the film. An electric heating element then delivers a quick, controlled heat pulse, securely bonding the film around the product before the shrink process begins.Q: What types of films are compatible with this food shrink wrap machine?

A: This machine is compatible with PVC, Polyolefin, and POF films, providing flexibility to select the best material for various packaging needs across food, bakery, and retail products.Q: When is it necessary to adjust the operating temperature and shrink speed?

A: Temperature and shrink speed adjustments are necessary when switching between different film types or product thicknesses. The machine operates efficiently between 120-200C and allows users to optimize shrink speed, ensuring the best fit and protection for each product type.Q: Where is this machine typically used in the food industry?

A: This machine is ideal for use in food packaging facilities, bakeries, and retail stores. Its portable, countertop design makes it suitable for both small businesses and high-output production areas where space efficiency and mobility are valued.Q: What is the typical process for shrink wrapping items with this machine?

A: Place the item on the packaging table, wrap it using a compatible shrink film, and initiate sealing with the manual impulse system. Once sealed, activate the heating element to shrink the film, ensuring a tight, secure finish around your product. The adjustable controls let you tailor the process to a wide range of items.Q: How does the overheat protection benefit daily usage?

A: The built-in overheat protection ensures the machine automatically shuts off or regulates heating if the temperature exceeds safe limits, protecting both the user and the equipment during prolonged or intensive use.Q: What after-sales support is available for this machine in India?

A: Comprehensive after-sales service is provided, including technical support, troubleshooting, and maintenance assistance, ensuring your machine remains reliable and efficient over time.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Shrink Wrapping Machine Category

Shrink Tunnel Machine

Price 34500 INR / Unit

Minimum Order Quantity : 1 Unit

Material : Mild Steel

Automatic Grade : SemiAutomatic

Color : Gray & Orange

A4 Paper Box Shrink Wrapping Machine

Price 34500 INR / Unit

Minimum Order Quantity : 01 Unit

Material : Stainless Steel

Automatic Grade : SemiAutomatic

Warranty : 1 Year

Color : Blue and Red

Bbook Shrink Wrapping Machine

Price 34500 INR / Unit

Minimum Order Quantity : 01 Unit

Material : Metal

Automatic Grade : SemiAutomatic

Warranty : 12 months

Color : Blue and red

HEAT SHRINK MACHINE

Price 34500.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Material : Mild Steel

Automatic Grade : SemiAutomatic

Warranty : 1 year

Color : Blue

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry