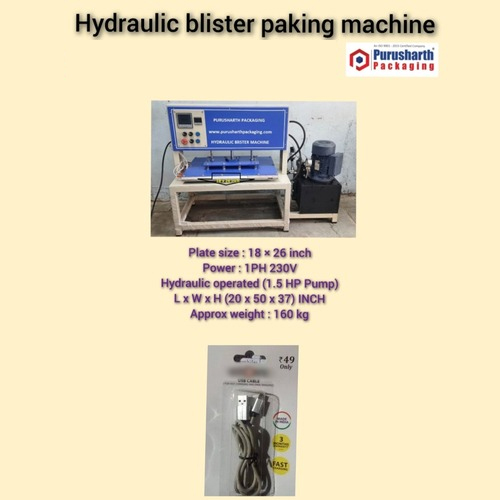

Data Cable Blister Packing Machine

Price 90000.0 INR/ Unit

Data Cable Blister Packing Machine Specification

- Application

- Blister packing for data cables and other products

- Features

- Durable efficient performance

- Usage

- Suitable for packaging data cables and similar products

- Power Supply

- 220V

- Type

- Other

- Material

- Metal

- Feature

- Other

- Auxiliary Packaging Machine Type

- Other

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Drive Type

- Hydraulic

- Power

- 1HP Horsepower (HP)

- Voltage

- 220V Volt (v)

- Weight (kg)

- 140 kg Kilograms (kg)

- Dimension (L*W*H)

- 20 x 16 x 27 inches Inch (in)

- Color

- White

- Warranty

- Standard warranty as per manufacturer

- Sealing Type

- Heat Sealing

Data Cable Blister Packing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 100 Units Per Month

- Delivery Time

- 7 Days

About Data Cable Blister Packing Machine

A Data Cable Blister Packing Machine is designed to package data cables efficiently in protective blister packs. Key components include a heat-sealing system, a forming station, and a cutting mechanism. It uses automatic or semi-automatic operating systems for high-speed production. Types include manual, semi-automatic, and fully automatic models. It ensures precise blister formation, sealing, and cutting for safety and durability. Common in the electronics, telecom, and consumer goods industries, it enhances product protection and presentation. Manufactured using advanced technologies like PLC controls and servo motors, the machine offers high performance, low maintenance, and customizable packaging solutions for various cable types.

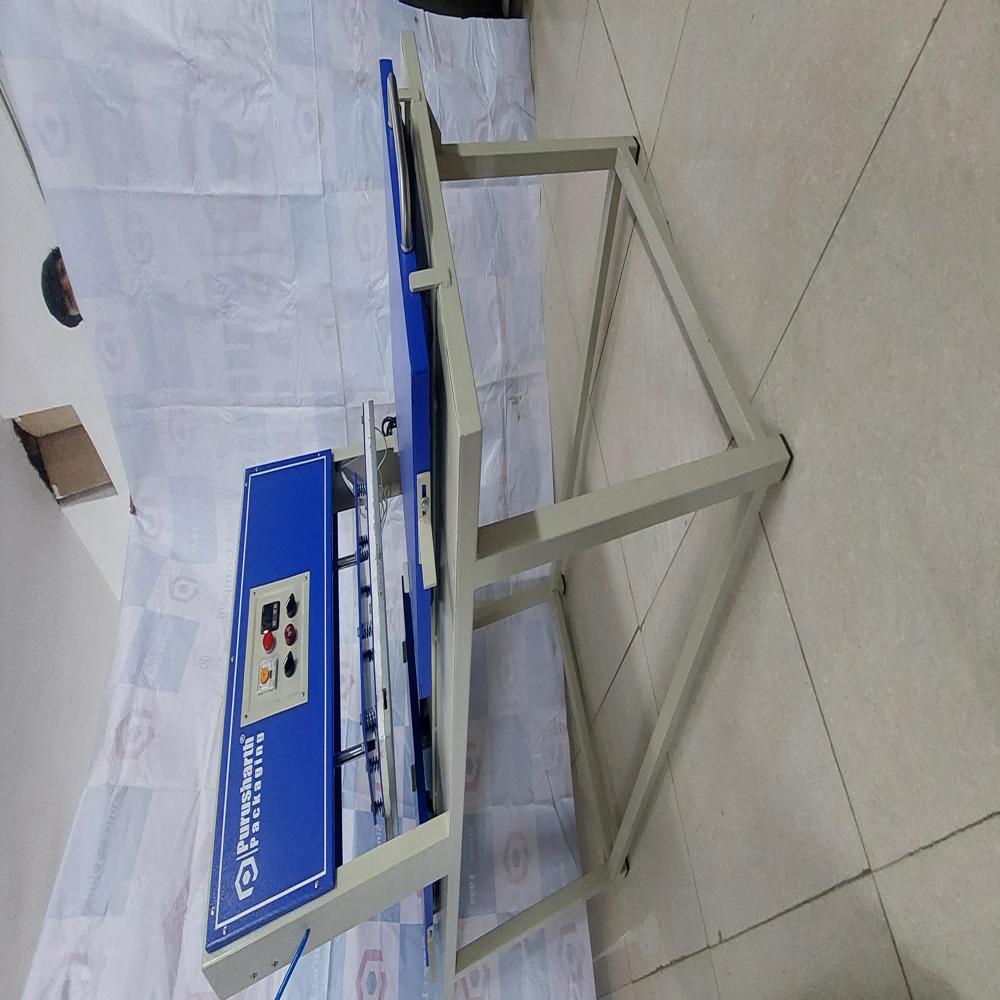

- Plate size : 18 x 26 inch

- Power : 1 PH 230V

- Hydraulic operated (1.5 HP Pump0

- L x W x H ( 20 x 50 x 37 ) INCH

- Approx weight : 160 KG

The Data Cable Blister Packaging Machine is essential equipment for the electronics and accessories industry, designed to efficiently and attractively package various types of cables (USB, charging, audio, HDMI, etc.) for retail sale.1

It converts rolls of plastic and pre-printed cards into finished, protective, and secure retail packages.

Core Function and Retail Importance

Data cables are often packaged using a blister pack because of its ideal combination of protection, visibility, and security.

-

Visibility: The clear plastic blister allows customers to see the cables quality, length, and connectors (USB-C, Lightning, etc.), which is critical for making a purchase decision.

-

Protection: It securely holds the coiled cable and connectors in place, preventing tangling, kinking, or damage to the delicate plug pins during shipping and display.2

-

Tamper Evidence: A properly sealed blister pack is tamper-evident, ensuring the consumer receives a brand-new, untampered product, which helps reduce retail theft.

Machine Features and Operation

Data cable blister packaging machines are often semi-automatic (hydraulic drive is common) to allow for the manual loading of the coiled, irregular-shaped cable while automating the precision steps of forming and sealing.3

| Component/Step | Description & Benefit for Cables |

| Blister Forming | Heats a roll of PVC or PET plastic and uses vacuum/pressure over a mold to create the custom-shaped cavity designed to hold the coiled cable and its connectors. |

| Product Loading | Due to the variance in cable coiling, this is often a manual station, where the operator places the cable and the pre-printed cardboard backing into the mold. |

| High-Pressure Sealing | The most critical step. The machine applies precisely controlled heat and pressure to fuse the plastic blister to the heat-activated coating on the cardboard. Hydraulic or pneumatic drives ensure a strong, uniform seal across the entire package. |

| Changeover Tooling | Requires interchangeable molds/dies to accommodate the different sizes of cables (short phone cables vs. long device cables) and the varying blister card designs. |

| Automatic Cutting | The sealed packages are automatically cut or punched out into their final retail shape (often with a hanger hole for retail display). |

Durable and Efficient Operation

Crafted with a strong metal construction and hydraulic drive, this blister packing machine ensures durability and consistent performance. The 1HP motor delivers powerful and efficient packaging for high-volume operations, making it suitable for various industrial applications. The heat sealing feature guarantees thoroughly sealed packages for products such as data cables.

User-Friendly Semi-Automatic Design

The machines semi-automatic grade simplifies the packaging process, allowing for easy setup and operation. Its compact dimensions save space, and the intuitive controls enable operators to work efficiently without extensive training. Manual intervention is minimal, ensuring reliable and repeatable results every cycle.

Versatile Applications in Electronics

Primarily used for blister packaging data cables, this machine also accommodates similar products, adapting to various packaging needs in the electronics sector. Its versatility makes it an excellent choice for distributors, manufacturers, and suppliers seeking efficient and secure packing solutions in India.

FAQs of Data Cable Blister Packing Machine:

Q: How does the heat sealing process work on this blister packing machine?

A: The heat sealing process securely bonds the plastic blister to the backing material through the application of controlled heat and pressure. This method ensures a tamper-resistant package ideal for data cables and similar electronics.Q: What specific products can be packaged using this machine?

A: This machine is designed mainly for packaging data cables but is also suitable for other similarly sized electronic products requiring blister packaging.Q: When is it advisable to use this semi-automatic blister packing machine?

A: This machine is best used in operations requiring moderate to high-volume packaging, where efficiency, product protection, and repeatability are important, such as in assembly lines or small-scale manufacturing.Q: Where should the machine be installed for optimal use?

A: Install the machine in a well-ventilated workspace with stable electricity supply (220V) and ample room for loading, unloading, and basic maintenance. Its compact size allows flexible placement on production floors.Q: What is the main process for operating the machine?

A: Operators load the blister, insert the product, activate the hydraulic heat sealing cycle, and then remove the finished package. The semi-automatic operation streamlines the workflow while maintaining packaging consistency.Q: What are the advantages of using this blister packing machine for businesses?

A: Key benefits include enhanced product protection, secure tamper-evident packaging, reduced manual labor, and higher productivity. Its durable build and efficient hydraulic drive support long-term industrial use.Q: Is technical expertise required to use the machine effectively?

A: The machines semi-automatic design minimizes the need for specialized technical knowledge. Basic operator training is sufficient for safe and efficient operation, making it accessible for most staff.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BLISTER PACKING MACHINE Category

Earphone packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 01 Unit

Features : Easy operation and precise control

Auxiliary Packaging Machine Type : Blister Packaging, Other

Drive Type : Hydraulic

Power Supply : Hydraulic (3.5 HP Pump)

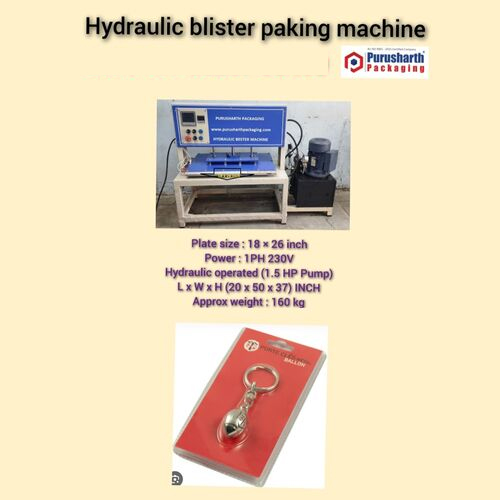

keychain packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Hydraulic operation compact design

Auxiliary Packaging Machine Type : Other, Blister Packing Machine

Drive Type : Other, Hydraulicoperated (0.5 HP Pump)

Power Supply : 220V

toys and games packing machine(hydrauclic blister machine)

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Durable efficient performance

Auxiliary Packaging Machine Type : Other

Drive Type : Hydraulic

Power Supply : 220V

Screw Driver Blister Packing Machine

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Hydraulic operation adjustable settings

Auxiliary Packaging Machine Type : Other

Drive Type : Hydraulic

Power Supply : 1PH 230V

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry