toys and games packing machine(hydrauclic blister machine)

Price 90000.0 INR/ Unit

toys and games packing machine(hydrauclic blister machine) Specification

- Usage

- Suitable for packaging data cables and similar products

- Features

- Durable efficient performance

- Power Supply

- 220V

- Application

- Blister packing for data cables and other products

- Type

- Blister Packaging Machines

- Material

- Metal

- Auxiliary Packaging Machine Type

- Other

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Drive Type

- Hydraulic

- Power

- 1 Horsepower (HP)

- Voltage

- 230 Volt (v)

- Weight (kg)

- 160 Kilograms (kg)

- Dimension (L*W*H)

- 20 x 16 x 27 inches Inch (in)

- Color

- White

- Warranty

- Standard warranty as per manufacturer

toys and games packing machine(hydrauclic blister machine) Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Main Export Market(s)

- North America, Eastern Europe, Western Europe, Australia, Central America, Asia, South America, Middle East, Africa

- Main Domestic Market

- All India

About toys and games packing machine(hydrauclic blister machine)

Click Here to Watch Video

A hydraulic blister machine is a specialized piece of industrial equipment designed for forming and sealing blister packs. These machines use hydraulic pressure to shape plastic into blisters and secure products within a protective packaging. They are commonly used across various industries, including pharmaceuticals, consumer goods, and food packaging.

The Toys and Games Blister Packaging Machine is a specialized piece of equipment designed to create visually appealing, protective, and tamper-evident packaging for a vast array of consumer retail products, from small figurines and toy cars to board game accessories and puzzle components.

This type of packaging is a staple in the toy industry because it perfectly balances marketing needs (product visibility) with logistical requirements (security and protection).

Core Function and Retail Advantage

The primary goal of the machine is to secure an irregular or small toy/game piece within a rigid, clear plastic bubble (the blister) and seal it firmly onto a pre-printed cardboard backing card.

Key Benefits for Toys and Games:

-

Maximum Product Visibility: The clear plastic blister offers 360-degree viewing, allowing children and parents to clearly see the actual product, which significantly drives impulse purchases.

-

Protection from Damage: It securely holds the toy, protecting delicate parts, sharp edges, or fragile electronics from bending or breaking during shipping, handling, and display.

-

Theft Deterrence: A tightly heat-sealed blister pack is tamper-evident and difficult to open without visible destruction, which is a major deterrent to retail theft.

-

Hanging/Display: The packaging is universally designed with a punch-out hang hole, making it perfectly suited for displaying on retail pegboards.

Machine Operation and Adaptability

Due to the highly irregular shapes of toys and game pieces, these machines often operate in a semi-automatic mode, optimizing speed while maintaining flexibility.

| Station | Function in Toy Packaging |

| Forming Station | Uses heat and vacuum to mold PVC or PET plastic into a custom cavity shape that perfectly matches the contours of the toy (e.g., a car, an action figure, or a plastic weapon). |

| Product Loading | Often Manual or assisted by robotic pick-and-place, as the complex, varied shapes of toys require careful, precise placement into the blister cavity. |

| Card Feeding | Automatically places the pre-printed, glue-coated cardboard backing over the toy-filled blister. |

| Heat Sealing | The sealing plate applies controlled heat and pressure (often using hydraulic or pneumatic power) to create a strong, permanent bond between the plastic blister flange and the cardboard. |

| Die Cutting/Punching | The final step, where the finished package is accurately cut to the desired shape (often incorporating rounded corners and the essential hanger hole). |

Versatile Blister Packing Solution

Our hydraulic blister packaging machine is designed to handle toys, games, data cables, and related products with ease. Its robust metal construction guarantees longevity and consistent output, catering to a variety of packaging requirements in commercial and industrial settings.

Semi-Automatic Operation for Enhanced Efficiency

This machine delivers a balance between manual control and mechanical precision. Users simply load products and initiate the blister packaging process, which streamlines productivity while maintaining quality for different packaging sizes and shapes.

Optimized for Indian Market Needs

With a voltage compatibility of 220V to 230V and a durable, efficient structure, this blister packing machine is perfectly suited for Indian distributors, exporters, manufacturers, and traders seeking reliable packaging solutions for their business.

FAQs of toys and games packing machine(hydrauclic blister machine):

Q: How does the hydraulic blister packaging machine operate?

A: The machine uses hydraulic pressure to seal products, such as data cables, within blister packs. Operators place the product and packaging materials on the designated area, initiate the process, and the hydraulic system securely seals the pack, ensuring strong and neat packaging.Q: What types of products can be packaged using this machine?

A: It is suitable for packaging data cables, toys, games, and other similar small-to-medium-sized items that benefit from secure, tamper-evident blister packs.Q: When is it ideal to use this blister packing machine?

A: This machine is ideal for businesses needing reliable, semi-automatic packaging for medium-volume production runs. Its perfect for manufacturers, exporters, and suppliers dealing in electronics accessories, toys, and games.Q: Where can this machine be installed and used efficiently?

A: Due to its compact dimensions (20 x 16 x 27 inches), the machine is suitable for installation in factories, small workshops, or commercial packaging units across India that require efficient use of space.Q: What is the process involved in blister packing with this equipment?

A: The operator places the product and blister material on the machine tray, aligns it, and activates the hydraulic system. The machine applies pressure and heat to create a firm, sealed blister pack, ready for market distribution.Q: How does the semi-automatic feature benefit my business?

A: The semi-automatic design offers greater control over the packaging process, increases efficiency compared to manual options, and enables consistent packaging quality with minimal operator intervention.Q: What are the advantages of choosing this hydraulic blister packing machine?

A: Key benefits include its durable metal construction, reliable hydraulic drive, efficient performance, standard manufacturer warranty, and suitability for a wide range of packaging needs, all tailored to Indian voltage and usage conditions.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BLISTER PACKING MACHINE Category

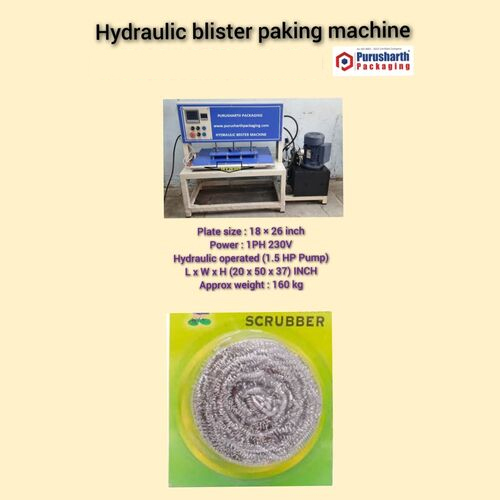

Stainless steel scrubber packing machine

Price 98500.0 INR / Unit

Minimum Order Quantity : 1 Piece

Power Supply : Singlephase 220V

Features : Hydraulic operation semiautomatic process

Weight (kg) : 100 kg Kilograms (kg)

Dimension (L*W*H) : 18 x 28 inch Inch (in)

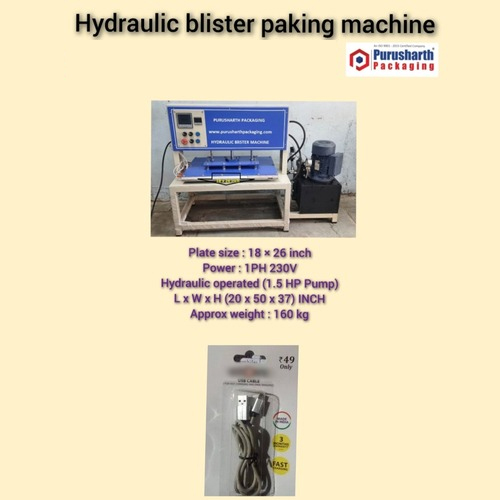

Data Cable Blister Packing Machine

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Power Supply : 220V

Features : Durable efficient performance

Weight (kg) : 140 kg Kilograms (kg)

Dimension (L*W*H) : 20 x 16 x 27 inches Inch (in)

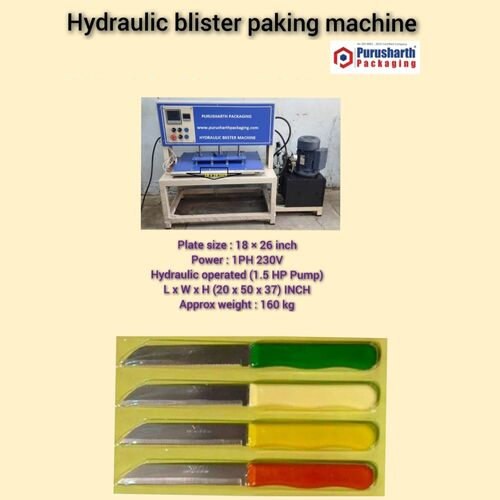

Knife packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 01 Unit

Power Supply : 230V

Features : Hydraulic mechanism Compact design

Weight (kg) : 160 kg

Dimension (L*W*H) : 18 x 24 inch (Plate Size)

Sanitizer packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 01 Unit

Power Supply : 230V

Features : Hydraulic operated (0.5 HP Pump)

Weight (kg) : 160 kg

Dimension (L*W*H) : L x W x H (20 x 16 x 27) inch

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry