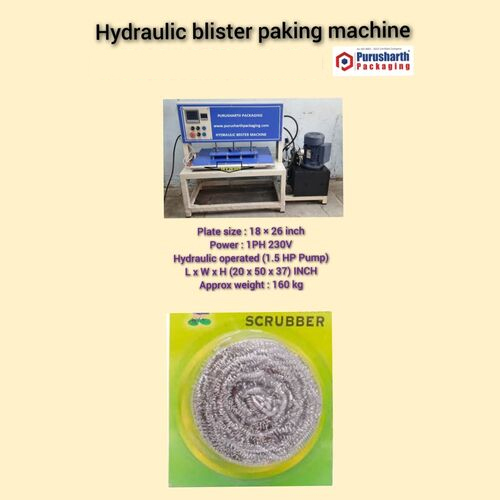

Stainless steel scrubber packing machine

Price 98500.0 INR/ Unit

Stainless steel scrubber packing machine Specification

- Application

- Stainless steel scrubber packing

- Features

- Hydraulic operation semi-automatic process

- Usage

- Packaging stainless steel scrubbers

- Power Supply

- Single-phase 220V

- Type

- Other

- Material

- Steel

- Feature

- Other

- Auxiliary Packaging Machine Type

- Other

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Drive Type

- Hydraulic

- Power

- 1500W Watt (w)

- Voltage

- 220V Volt (v)

- Weight (kg)

- 100 kg Kilograms (kg)

- Dimension (L*W*H)

- 18 x 28 inch Inch (in)

- Sealing Type

- Other

Stainless steel scrubber packing machine Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 4 Days

- Sample Available

- No

- Packaging Details

- STANDARD AND SECURE PACKING

- Main Export Market(s)

- Central America, South America, Eastern Europe, Africa, Asia, Australia, North America, Western Europe, Middle East

- Main Domestic Market

- All India

- Certifications

- ISO CERTIFIED

About Stainless steel scrubber packing machine

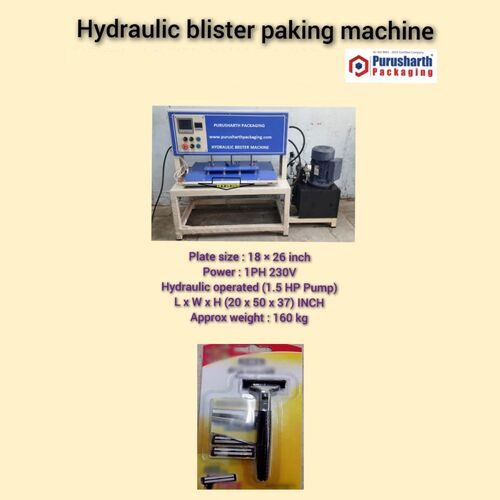

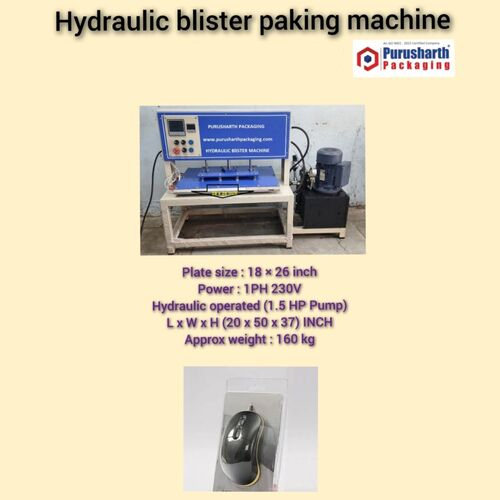

Plate size : 18 x 26 inch

Power : 1 PH 230V

Hydraulic operated (1.5 HP Pump0

L x W x H ( 20 x 50 x 37 ) INCH

Approx weight : 160 KGThe Scrubber Blister Packaging Machine is a high-performance, automated solution designed specifically for packaging kitchen scrubbers in sealed, tamper-evident blister packs. Engineered for efficiency and reliability, this machine ensures consistent packaging quality while maximizing throughput and minimizing labor costs.

Efficient and Durable Packaging Solution

This stainless steel scrubber packing machine is designed for reliability and efficiency. With hydraulic operation and semi-automatic functionality, it increases output while minimizing operator fatigue. Its sturdy steel construction and compact size make it ideal for a wide range of industrial environments, from manufacturing plants to export warehouses.

User-Friendly Operation and Installation

The machine runs on a standard 220V single-phase power supply, making installation straightforward. Its semi-automatic process requires minimal training for operators, enabling quick adoption in your workflow. The hydraulic drive system ensures smooth performance and sustained output over long periods.

FAQs of Stainless steel scrubber packing machine:

Q: How does the semi-automatic process of this stainless steel scrubber packing machine work?

A: The machine utilizes hydraulic operation to automate most of the scrubber packaging steps, requiring only basic manual supervision. Operators simply load the scrubbers and initiate the process, after which the machine packages them efficiently.Q: What are the key benefits of using this machine for scrubber packaging?

A: Key benefits include increased productivity, consistent packing quality, reduced manual labor, and durability due to its steel construction. The hydraulic system ensures reliable performance and long operational life.Q: When is it ideal to use a semi-automatic packing machine over a fully automatic one?

A: A semi-automatic machine is suitable when you require flexibility, lower investment costs, or operate on a small to medium scale. It is ideal for setups where some manual intervention is manageable or desirable for quality control.Q: Where can this stainless steel scrubber packing machine be installed?

A: Due to its compact dimensions (18 x 28 inches) and single-phase 220V power requirement, the machine can be installed in most industrial facilities, manufacturing units, or workshops that have standard electrical infrastructure.Q: What is the typical process for installing and starting this machine?

A: Installation involves placing the machine in a suitable workspace, connecting it to a 220V power source, and ensuring proper hydraulic fluid levels. After a brief operator training session, it is ready for daily packaging operations.Q: How is maintenance carried out for this machine?

A: Regular maintenance includes checking and topping up hydraulic fluids, inspecting parts for wear, and occasional cleaning. Its steel build makes upkeep relatively straightforward and cost-effective.Q: What makes this machine a beneficial investment for distributors and exporters?

A: With reliable performance, low operational costs, and semi-automatic function, distributors and exporters can achieve faster packing, maintain product quality, and optimize labor usegiving them an edge in competitive stainless steel scrubber markets.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BLISTER PACKING MACHINE Category

toys and games packing machine(hydrauclic blister machine)

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Auxiliary Packaging Machine Type : Other

Material : Metal

Drive Type : Hydraulic

Power : 1 Horsepower (HP)

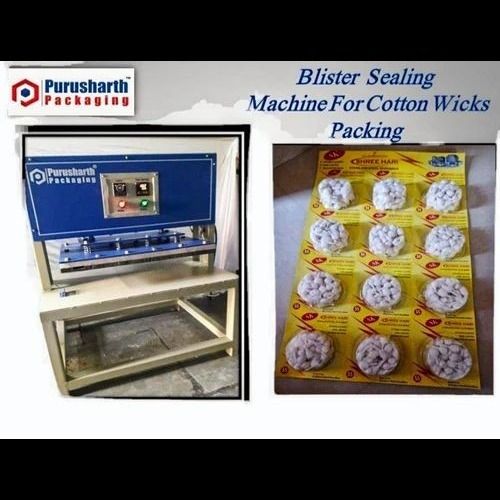

Cotton Wick Packing Machine

Price 48500 INR / Unit

Minimum Order Quantity : 01 Unit

Auxiliary Packaging Machine Type : Other, Blister Packing Machine

Material : Stainless steel and other sturdy materials

Drive Type : Electric

Power : Standard electric power

razor packaging machine

Price 98500 INR / Unit

Minimum Order Quantity : 01 Unit

Auxiliary Packaging Machine Type : Hydraulic, Other

Material : Metal and standard components

Drive Type : Hydraulic

Power : 1 HP

computer mouse packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 1 Unit

Auxiliary Packaging Machine Type : Other, Blister packing machine

Material : Metal

Drive Type : Hydraulic

Power : 1 HP

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry