Paneer packaging machine

Price 198500 INR/ Unit

Paneer packaging machine Specification

- Noise Level

- Low

- Usage

- Paneer vacuum packaging

- Application

- Paneer packaging

- Features

- Efficient for sealing and vacuum processing

- Power Supply

- 220V/50Hz

- Type

- Packaging machine

- Material

- Stainless Steel

- Feature

- Vacuum sealing

- Auxiliary Packaging Machine Type

- Vacuum Packaging Machine

- Capacity

- Double chamber

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Manual/Automatic

- Drive Type

- Electric

- Voltage

- 220V

- Color

- Stainless Steel

- Sealing Type

- Vacuum Sealing

About Paneer packaging machine

VACUUM CHAMBER STAINLESS STEEL FLAT WORKING PLATE

SEALING LENGTH : 620 X 10 mm

CAPACITY 40 m 3/h

CYCLE TIME 10-40 sec.

VOLTAGE 3 PHASE 380 V/50 Hz

POWER 1.5 KW & 3.1 KW

MACHINE SIZE 1450 x 750 x 1000 mm

WORKROOM SIZE 670 x 540 x 110 mm

WEIGHT 320 KG

Advanced Double Chamber Efficiency

Designed with a double chamber, this vacuum packaging machine significantly increases production capacity. The dual chamber system allows for simultaneous operations, boosting overall output and reducing downtime between sealing cycles. This feature is perfect for medium to large-scale paneer manufacturers seeking efficiency and throughput.

User-Friendly Computerized Controls

Equipped with both manual and automatic control modes, this machine offers flexibility and ease of operation. The computerized interface ensures consistent sealing performance, while manual overrides provide adaptability for specific packaging needs. Operators benefit from simplified training and reliable results.

Superior Stainless Steel Construction

Crafted from premium stainless steel, the machine promises long-term durability and resistance to rust or corrosion. This makes it ideal for food processing environments where hygiene and cleanliness are top priorities. Routine cleaning and maintenance are straightforward due to its robust build.

FAQs of Paneer packaging machine:

Q: How does the double chamber feature enhance the paneer packaging process?

A: The double chamber design allows for simultaneous vacuum sealing operations, enabling higher packaging throughput. While one chamber is in use, the other can be prepped, reducing downtime and enhancing packaging efficiency.Q: What is the process involved in vacuum sealing paneer with this machine?

A: Paneer blocks are placed in preformed bags, which are then positioned in the vacuum chamber. The machine removes air from the bags before automatically sealing them, ensuring the paneer remains fresh with an extended shelf life.Q: When should I use the manual versus the automatic control system?

A: The manual mode gives you flexibility for custom packaging requirements, while the automatic mode streamlines the operation for high-volume, continuous processing. Use the automatic setting for standard batches and manual for unique or experimental packaging needs.Q: Where is this paneer packaging machine typically installed?

A: This machine is ideal for food processing plants, paneer manufacturing facilities, or dairy packaging units across India. Its compact yet robust design makes it suitable for both small and large production areas.Q: What are the key benefits of vacuum sealing paneer with this packaging machine?

A: Vacuum sealing using this machine preserves freshness, prevents spoilage, and significantly extends the shelf life of paneer. It also offers protection from contaminants and improves product presentation for distributors and exporters.Q: How efficient is this machine in terms of energy consumption and noise levels?

A: Operating on a 220V electric power supply, the machine is energy-efficient and generates minimal noise, ensuring a pleasant working environment while maintaining high sealing performance.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Packaging Machine Category

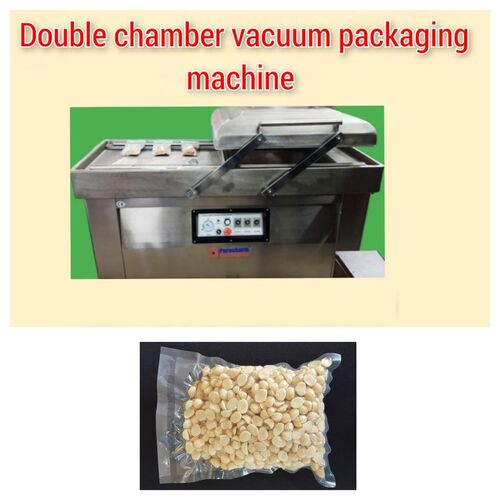

macadamia nuts vacuum packing machine

Price 198500.0 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic Grade : Automatic

Material : Stainless Steel

Voltage : 220V Volt (v)

Color : Other

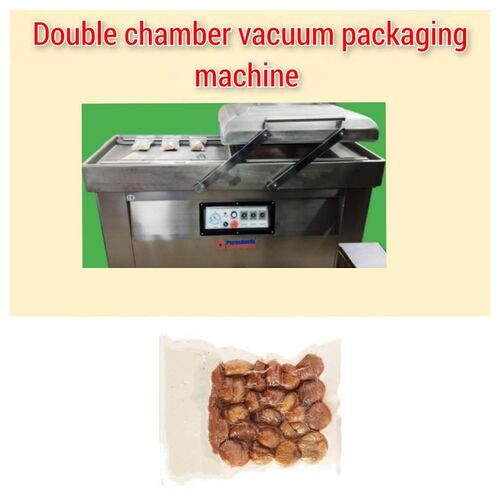

chestnut vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Material : Stainless Steel

Voltage : 220V Ohm (ohm)

Color : Other

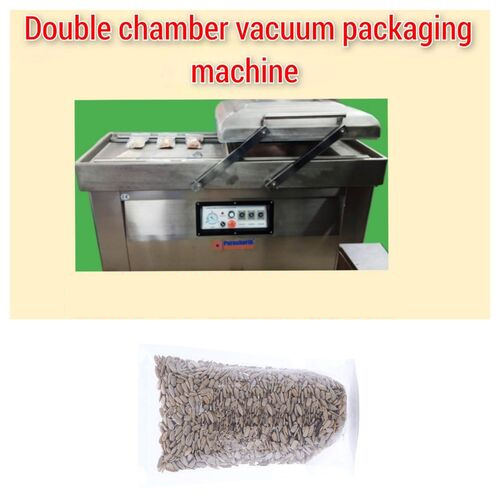

sunflower seeds vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Material : Stainless Steel

Voltage : 220V Volt (v)

Color : Other

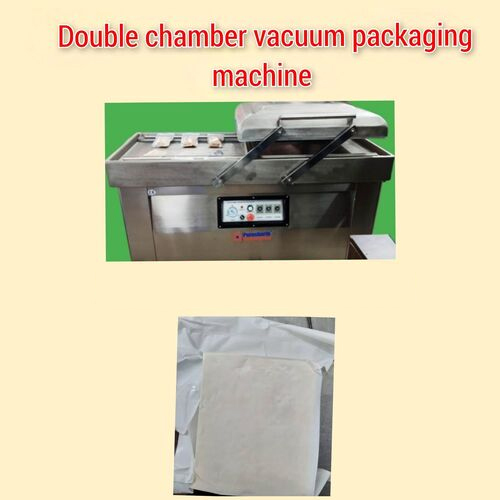

vacuum machine sealer

Price 135000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Automatic Grade : SemiAutomatic

Material : Mild Steel

Color : Silver

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry