Papad packing machine

Price 198500 INR/ Unit

Papad packing machine Specification

- Features

- Double Chamber Vacuum Sealing

- Power Supply

- Electric

- Noise Level

- Low

- Application

- Food Packaging

- Usage

- Papad and other food items packaging

- Type

- Packaging Machine

- Material

- Stainless Steel

- Feature

- Vacuum Packaging

- Auxiliary Packaging Machine Type

- Vacuum Packaging Machine

- Capacity

- Double Chamber

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Digital

- Drive Type

- Electric

- Color

- Silver

- Sealing Type

- Vacuum Sealing

About Papad packing machine

VACUUM CHAMBER STAINLESS STEEL FLAT WORKING PLATE

SEALING LENGTH : 620 X 10 mm

CAPACITY 40 m 3/h

CYCLE TIME 10-40 sec.

VOLTAGE 3 PHASE 380 V/50 Hz

POWER 1.5 KW & 3.1 KW

MACHINE SIZE 1450 x 750 x 1000 mm

WORKROOM SIZE 670 x 540 x 110 mm

WEIGHT 320 KG

Advanced Double Chamber Vacuum Sealing

Enhance production efficiency with our double chamber vacuum packaging machine. This feature allows for simultaneous packing cycles, significantly increasing throughput without compromising seal integrity. The machines robust stainless steel body ensures durability and hygiene in demanding food industry environments.

User-Friendly Digital Control System

The computerized digital control panel makes operation intuitive and straightforward. Easily configure settings for various packaging needs, guaranteeing optimal results for papads and other food products. The system ensures precision, reducing the risk of error and maximizing productivity.

Low Noise and High Capacity Operation

Engineered for quiet operation, this machine minimizes workplace disturbances while maintaining a high output due to its double chamber capacity. It is perfectly suited for both large-scale and small-scale food packaging units aiming for efficiency and consistent results.

FAQs of Papad packing machine:

Q: How does the Papad Packing Machine ensure long-lasting freshness of food items?

A: The machine utilizes advanced vacuum sealing technology that removes air from the package, preventing oxidation and moisture entry. This significantly extends the shelf life of papads and other food products by maintaining their freshness and flavor.Q: What are the main advantages of the double chamber vacuum system?

A: The double chamber system increases packing speed and efficiency, allowing operators to prepare one chamber while the other is sealing. This reduces downtime and boosts overall productivity in high-volume food packaging operations.Q: When should I use the digital control system during operation?

A: The digital control panel should be used at every packaging session to set precise parameters, such as vacuum time and sealing duration, ensuring each batch is packed under optimal conditions tailored to the product type.Q: Where can this vacuum packaging machine be installed and used?

A: Designed for versatile installation, this machine is suitable for food processing units, packaging factories, or commercial kitchens. It caters to the needs of distributors, exporters, manufacturers, suppliers, and service providers across India.Q: What is the general process for packaging papad with this machine?

A: Simply place the papads in the designated packaging bags, position them in the vacuum chamber, and close the lid. Select the appropriate settings on the digital control panel, and the machine will automatically vacuum out air, seal the package, and prepare it for removal.Q: How does the machine support compliance with food safety standards?

A: Constructed from food-grade stainless steel and equipped with an airtight vacuum sealing system, the machine helps uphold hygiene and safety standards. Its easy-to-clean surfaces and reliable sealing process protect the integrity of food products.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vacuum Packaging Machine Category

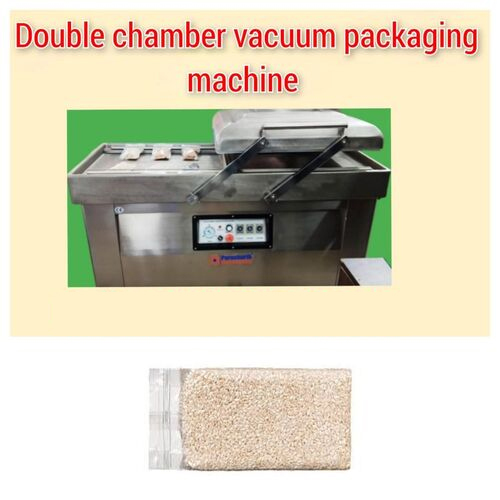

sesame seeds vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Feature : Other

Type : Other

Color : Other

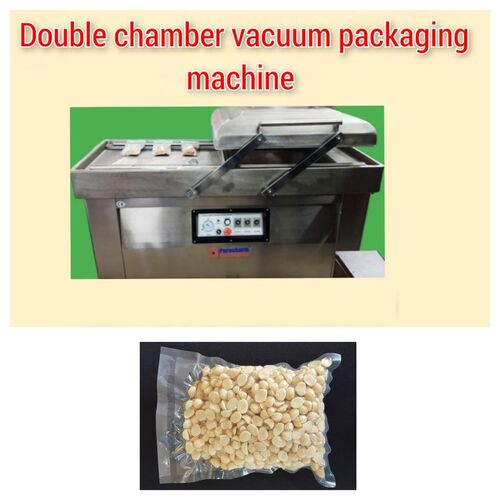

macadamia nuts vacuum packing machine

Price 198500.0 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic Grade : Automatic

Feature : Other

Type : Other

Color : Other

Paneer packaging machine

Price 198500 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic Grade : Automatic

Feature : Other, Vacuum sealing

Type : Packaging machine, Other

Color : Other, Stainless Steel

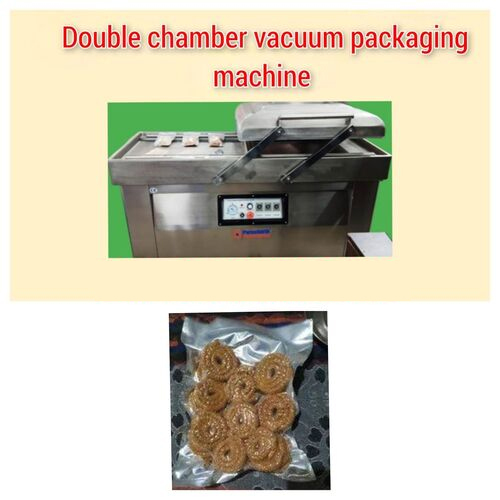

chakli vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Feature : Other

Type : Other

Color : Silver

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry