tea packing machine

Price 198500 INR/ Unit

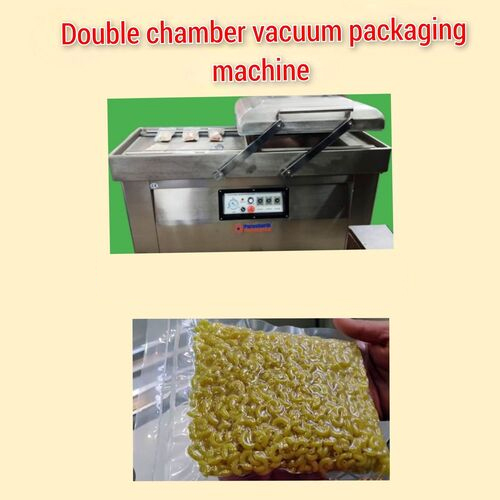

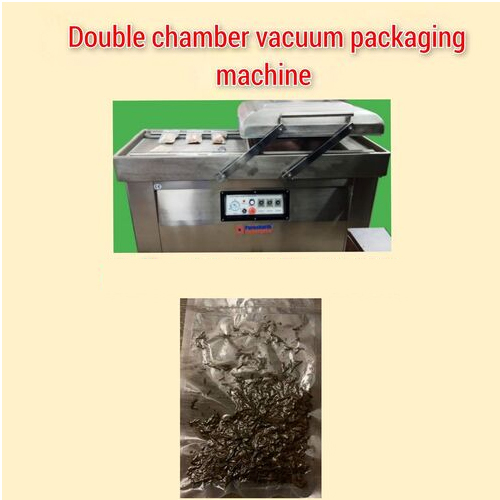

tea packing machine Specification

- Application

- Tea Packaging

- Filling Range

- Supports multiple bag sizes

- Usage

- Food Packaging (specifically tea packaging)

- Power Supply

- 220V/50Hz

- Noise Level

- Low

- Features

- Double chamber for increased efficiency

- Type

- Vacuum Packaging Machine

- Material

- Stainless Steel

- Auxiliary Packaging Machine Type

- Double Chamber Vacuum Packaging Machine

- Capacity

- Varies depending on bag size

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Digital Control System

- Drive Type

- Electric

- Power

- Standard power rating suggest electric consumption details

- Voltage

- 220V

- Weight (kg)

- Varies depending on model

- Dimension (L*W*H)

- Standard dimensions refer to product specification sheet

- Color

- Silver

- Warranty

- 1 year

- Sealing Type

- Vacuum seal

About tea packing machine

VACUUM CHAMBER STAINLESS STEEL FLAT WORKING PLATE

SEALING LENGTH : 620 X 10 mm

CAPACITY 40 m 3/h

CYCLE TIME 10-40 sec.

VOLTAGE 3 PHASE 380 V/50 Hz

POWER 1.5 KW & 3.1 KW

MACHINE SIZE 1450 x 750 x 1000 mm

WORKROOM SIZE 670 x 540 x 110 mm

WEIGHT 320 KG

Optimize Tea Packaging with Advanced Vacuum Sealing

Enhance your tea products quality and longevity with our double chamber vacuum packaging machine. Equipped with an intelligent digital control system and designed for automatic operation, this equipment ensures fast, airtight packaging. Suitable for various tea bag sizes, its robust stainless steel construction and low-noise performance make it ideal for large-scale commercial operations. The vacuum seal mechanism not only preserves aroma and flavor but also streamlines packaging efficiency for businesses.

Versatility and Efficiency for Diverse Tea Producers

Whether you are an exporter, supplier, or manufacturer, this tea packing machine adapts to a range of production scales. Its variable capacity and filling ranges address the differing demands of tea packaging, while the double chamber setup accelerates batch processing. The computerized system delivers consistent output, ensuring your tea products meet market standards and customer expectations.

FAQs of tea packing machine:

Q: How does the vacuum sealing process benefit tea packaging?

A: Vacuum sealing efficiently removes air from the packaging, helping to prevent oxidation, preserve the teas natural aroma and taste, and significantly extend shelf life.Q: What bag sizes can this machine accommodate?

A: This machine supports a broad filling range and is designed to handle multiple tea bag sizes, allowing for packaging flexibility based on your product requirements.Q: When should the machine be serviced under warranty?

A: You should service the machine within the 1-year warranty period if any performance or operational issues arise. Service guidelines are provided in the user manual and through authorized service agents.Q: Where can I find the dimensions and installation requirements for the machine?

A: Standard machine dimensions are available in the product specification sheet, which details all necessary requirements for installation and setup in your facility.Q: What is the process for automatic tea packing using this machine?

A: The process involves loading tea into the designated chamber, selecting the appropriate digital controls for bag size and vacuum duration, and allowing the machine to seal and pack the product automatically.Q: How does the double chamber design improve efficiency?

A: With two chambers, one chamber can be loaded or unloaded while the other operates, significantly reducing downtime and increasing packaging throughput.Q: What are the key usage advantages for distributors and manufacturers?

A: The machines digital control and double chamber features boost productivity, reduce manual intervention, ensure consistent packaging quality, and help businesses deliver fresh tea products efficiently to their customers.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VACUUM Packing Machine Category

Pineapple packing machine

Price 198500 INR / Unit

Minimum Order Quantity : 01 Unit

Color : Silver

Material : Stainless steel

Automatic Grade : Automatic

Usage : Commercial pineapple packaging

pasta packing machine

Price 198500 INR / Unit

Minimum Order Quantity : 01 Unit

Color : Silver

Material : Stainless steel

Automatic Grade : Automatic

Usage : Packaging pasta and vacuumsealing food items

Powder Packing Machine

Price 54500.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Color : Blue

Material : Mild Steel

Automatic Grade : SemiAutomatic

Usage : Industrial

Mineral Water Bottle Packing Machine

Price 243500.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Color : Blue

Material : Stainless Steel

Automatic Grade : Automatic

Usage : Industrial

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry