wafer packing machine

Price 198500 INR/ Unit

wafer packing machine Specification

- Filling Range

- Not specified in the image

- Usage

- Vacuum packaging for food (e.g. wafers chips etc.)

- Application

- Food Packaging

- Features

- Double chamber operation vacuum sealing

- Power Supply

- Electric

- Noise Level

- Low

- Type

- Double Chamber Vacuum Packaging Machine

- Material

- Stainless Steel

- Feature

- Efficient sealing for vacuum-packed products

- Auxiliary Packaging Machine Type

- Vacuum Packaging Machine

- Capacity

- Double Chamber

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Digital Control Panel

- Drive Type

- Electric

- Power

- Not specified in the image

- Voltage

- Not specified in the image

- Weight (kg)

- Not specified in the image

- Dimension (L*W*H)

- Not specified in the image

- Color

- Silver

- Warranty

- Not specified in the image

- Sealing Type

- Vacuum Seal

About wafer packing machine

VACUUM CHAMBER STAINLESS STEEL FLAT WORKING PLATE

SEALING LENGTH : 620 X 10 mm

CAPACITY 40 m 3/h

CYCLE TIME 10-40 sec.

VOLTAGE 3 PHASE 380 V/50 Hz

POWER 1.5 KW & 3.1 KW

MACHINE SIZE 1450 x 750 x 1000 mm

WORKROOM SIZE 670 x 540 x 110 mm

WEIGHT 320 KG

Efficient Double Chamber Design

The machines double chamber construction allows for simultaneous packaging, which accelerates operational efficiency. This feature is particularly advantageous for businesses handling large volumes, as it minimizes downtime between cycles and streamlines production, ultimately supporting faster throughput and better resource management.

Advanced Digital Control Panel

Equipped with a user-friendly computerized digital control panel, the machine offers precise adjustments for various packaging parameters. Operators can easily set and monitor sealing times, vacuum intensity, and other critical functions, ensuring optimal packaging for different food products such as wafers and chips.

Hygienic and Durable Stainless Steel Build

Crafted with high-grade stainless steel, the wafer packing machine is durable and easy to maintain, ensuring long-term hygiene compliance for food packaging environments. The robust material resists corrosion and ensures the machine remains in peak condition even after extensive use.

FAQs of wafer packing machine:

Q: How does the double chamber vacuum packaging process work on this machine?

A: The double chamber vacuum packing machine operates by placing food items, such as wafers or chips, in the vacuum bags and positioning them within each chamber. When the lid closes, air is extracted to create a vacuum, followed by an automatic heat seal to preserve freshness. The double chamber design enables continuous workflow, as one chamber can be loaded while the other completes the cycle.Q: What types of food items can be packed using this wafer packing machine?

A: This machine is versatile and primarily designed for vacuum-sealing snacks like wafers, chips, and other similar food products. Its efficient sealing preserves the taste, quality, and shelf-life of a variety of dry snacks and light food items.Q: When should I use a double chamber vacuum packaging machine instead of a single chamber model?

A: A double chamber vacuum packaging machine is ideal for high-volume packaging environments where consistent productivity is required. If your operation involves frequent or large-batch packagingsuch as in commercial food processing units, factories, or packaging centersa double chamber system streamlines workflow and increases output.Q: Where can this wafer packing machine be installed or used?

A: The machine is suitable for commercial settings, including wafer manufacturing plants, snack packaging facilities, and food processing units throughout India. Its robust design fits well in environments that require reliable, automated vacuum sealing of snacks and light food products.Q: What are the key benefits of vacuum sealing food with this machine?

A: Vacuum sealing with this machine extends food shelf life by reducing air exposure, locks in freshness, and protects against contamination. Additionally, its double chamber operation and computerized controls maximize efficiency and ensure consistent, quality sealing for all packaged goods.Q: Is this machine easy to operate and maintain?

A: Yes, the wafer packing machine features a computerized digital control panel for straightforward operation. Its stainless steel construction also simplifies cleaning and maintenance, supporting long-term durability and total hygiene in food-grade environments.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VACUUM Packing Machine Category

Thepla packing machine

Price 198500 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic Grade : Automatic

Color : Other, Silver metallic

Material : Stainless steel

Drive Type : Electric

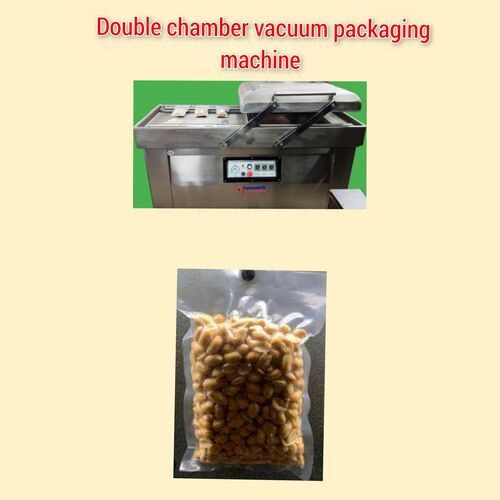

Peanuts packing machine

Price 198500 INR / Unit

Minimum Order Quantity : 01 Unit

Automatic Grade : Automatic

Color : Silver

Material : Stainless Steel

Drive Type : Electric

Dates vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : SemiAutomatic

Color : Other

Material : Stainless steel

Drive Type : Electric

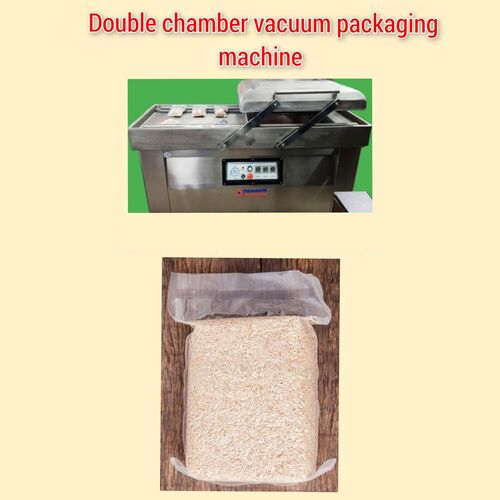

rice vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Automatic Grade : Automatic

Color : Silver

Material : Stainless steel

Drive Type : Electric

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry