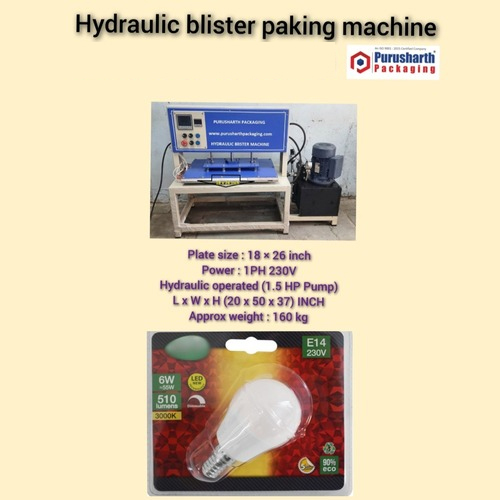

Led Bulb Blister Packing Machine

Price 90000.0 INR/ Unit

Led Bulb Blister Packing Machine Specification

- Power Supply

- 1 Phase 220V

- Usage

- Blister packing of LED Bulbs

- Features

- Plate Size: 18 x 26 inch

- Application

- Blister Packaging for LED Bulbs

- Material

- Metal (Machine Body)

- Auxiliary Packaging Machine Type

- Other

- Capacity

- 160 kg approx weight Kg/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Drive Type

- Hydraulic

- Power

- 3.3 HP Pump Horsepower (HP)

- Voltage

- 220V Volt (v)

- Weight (kg)

- 160 kg Kilograms (kg)

- Dimension (L*W*H)

- 20 x 50 x 37 inch Inch (in)

- Sealing Type

- Other

Led Bulb Blister Packing Machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

About Led Bulb Blister Packing Machine

The LED Bulb Blister Packing Machine is designed to efficiently package LED bulbs in protective blister packs, ensuring safe transportation and appealing display. Key components include a forming station, heat-sealing system, and automatic feeder. Available in manual, semi-automatic, and fully automatic types, it operates via PLC-controlled systems, offering high-speed, precision packaging. It is commonly used in the lighting, electronics, and retail industries. The machine features robust sealing, cutting, and product handling capabilities, offering enhanced durability and performance. Manufactured with advanced technologies like servo motors and touchscreens, it ensures minimal downtime, consistent output, and customization for different bulb sizes.

- Plate size : 18 x 26 inch

- Power : 1 PH 230V

- Hydraulic operated (1.5 HP Pump0

- L x W x H ( 20 x 50 x 37 ) INCH

- Approx weight : 160 KG

The LED Bulb Blister Packaging Machine is a specialized solution designed to package fragile LED lighting products securely and attractively for the retail market.1 Its primary function is to protect the delicate bulb and enhance its shelf presence.2

Here is a comprehensive description focusing on its benefits for the lighting industry:

Precision Packaging System for LED Bulbs

This machine is the essential end-of-line solution for LED bulb manufacturers, providing secure protection and optimal retail display via high-quality blister packaging.3 It is engineered to handle the delicate structure and various shapes (A-type, T-type, Candle, etc.) of LED bulbs and their components.

Key Advantages for LED Packaging

-

Damage Prevention: The thermoformed plastic blister creates a custom, rigid cavity that cradles the LED bulb, protecting the glass/plastic globe and sensitive electronics from impact and vibration during transport and handling.4

-

Visual Appeal: The clear blister offers maximum product visibility, allowing consumers to see the bulbs size, shape, and base type before purchase, driving retail sales.5

-

Retail Security: The precise heat-sealing process creates a tamper-evident, sealed package, crucial for high-volume retail environments to deter theft and ensure product integrity.

-

Versatility: The machine can quickly adapt to package various wattages and styles of LED bulbs, as well as smaller components like downlights or LED chips, by swapping out the custom tooling.

Operational Focus

LED bulb blister machines often utilize a semi-automatic or fully automatic system designed for high efficiency and consistent results:6

| Feature | Benefit for LED Bulbs |

| Precision Sealing | Automated heat and pressure control ensures a uniform seal between the blister (PVC/PET) and the card backing, vital for package durability. |

| Bulb Handling | Equipped with specialized molds to prevent the bulb from shifting or being damaged during the sealing cycle. |

| High Throughput | Designed for high-volume production, ensuring fast packaging rates to keep pace with demand in the competitive lighting market. |

| Automatic Functions | Many models feature automatic card feeding and blister cutting/punching, freeing up labor and ensuring accurate, clean final package edges. |

Efficient Semi-Automatic Blister Packaging

Benefit from a semi-automatic hydraulic drive that streamlines the blister packing process for LED bulbs. With a robust build and precise plate sizing, this machine ensures secure and professional packaging results, meeting the demands of high-volume operations.

Suitable for Versatile Applications

This machine is ideal for a range of business models, including manufacturers, suppliers, and exporters. Its versatility in handling different packaging requirements makes it a preferred choice for those involved in LED bulb distribution and service provision.

User-Friendly and Reliable Design

Built with a user-centric approach, the machine employs simple controls and clear operational guidelines, making it intuitive even for first-time users. Its metal construction and precise engineering provide durability while ensuring consistent performance.

FAQs of Led Bulb Blister Packing Machine:

Q: How does the LED Bulb Blister Packing Machine operate?

A: The machine operates in a semi-automatic mode using hydraulic drive. The operator loads the materials onto the 18 x 26-inch plate, initiates the hydraulic cycle, and the machine forms and seals the blister, securely packaging LED bulbs efficiently.Q: What is the recommended power supply for this packing machine?

A: This machine is designed to run on a single-phase 220V power supply, delivering a 3.3 HP via its hydraulic pump for reliable and consistent operation.Q: When should I consider using this machine for my production line?

A: If your business involves manufacturing or supplying LED bulbs and you require consistent, high-quality blister packaging, this machine is ideal for seamlessly integrating into your production workflow.Q: Where can the LED Bulb Blister Packing Machine be installed?

A: Due to its compact dimensions (20 x 50 x 37 inches) and manageable weight (160 kg), it can be installed in most industrial or workshop environments that meet the required electrical setup.Q: What is the process for blister packaging LED bulbs using this machine?

A: Place the LED bulbs and corresponding blister material on the machines plate, then activate the hydraulic cycle. The machine forms, seals, and cuts the packaging, providing a tightly enclosed product ready for distribution.Q: How does this machine benefit LED bulb manufacturers and suppliers?

A: It enhances productivity through fast and uniform blister packaging, reduces manual labor, and ensures a secure packaging solution that improves product presentation and protection during transport.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BLISTER PACKING MACHINE Category

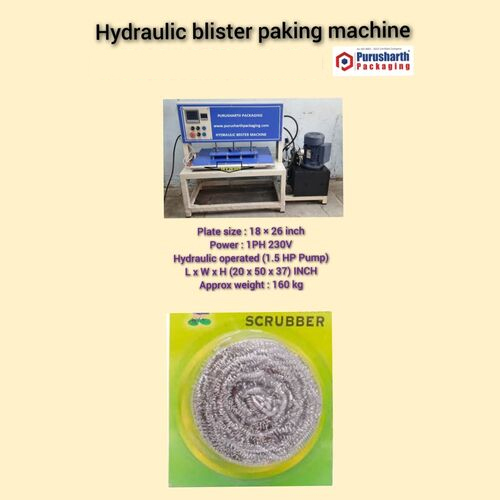

Stainless steel scrubber packing machine

Price 98500.0 INR / Unit

Minimum Order Quantity : 1 Piece

Weight (kg) : 100 kg Kilograms (kg)

Drive Type : Hydraulic

Automatic Grade : SemiAutomatic

Voltage : 220V Volt (v)

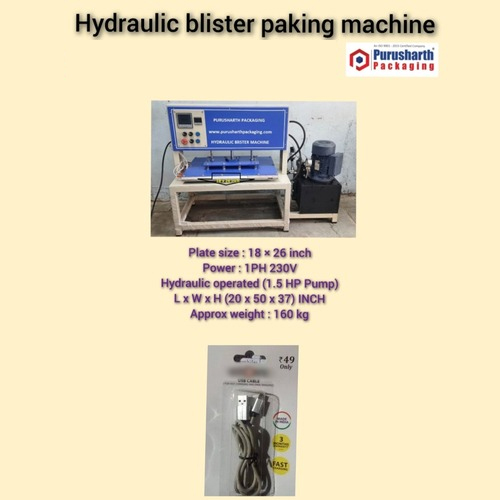

Data Cable Blister Packing Machine

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 140 kg Kilograms (kg)

Drive Type : Hydraulic

Automatic Grade : SemiAutomatic

Voltage : 220V Volt (v)

Stapler Blister Packing Machine

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 160 kg Kilograms (kg)

Drive Type : Hydraulic

Automatic Grade : SemiAutomatic

Voltage : 220V Volt (v)

Soldering Iron Blister Packing Machine

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Weight (kg) : 160 kg Kilograms (kg)

Drive Type : Hydraulic

Automatic Grade : Semi Automatic

Voltage : 220 Volt (v)

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry