supari packaging machine(vacuum sealing machine)

Price 32500.00 INR/ Unit

supari packaging machine(vacuum sealing machine) Specification

- Usage

- Industrial

- Features

- Good Quality

- Material

- MS

- Capacity

- 20 m3/hr

- Computerized

- No

- Automatic Grade

- Semi-Automatic

- Drive Type

- Electric

- Voltage

- 220 Volt (v)

- Weight (kg)

- 35 Kilograms (kg)

- Warranty

- 1 Year

supari packaging machine(vacuum sealing machine) Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 2 Units Per Day

- Delivery Time

- 1 Week

- Sample Available

- No

- Main Export Market(s)

- Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa, Asia

- Main Domestic Market

- All India

About supari packaging machine(vacuum sealing machine)

Click Here to Watch Video

A vacuum sealing machine is a device used to remove air from a package before sealing it. This process helps to extend the shelf life of food and other items by preventing spoilage and reducing oxidation. Heres a detailed description of a vacuum sealing machine:

Efficient Vacuum Sealing

Our supari packaging machine leverages vacuum sealing technology to preserve the quality and freshness of packed goods. Suitable for industrial environments, it achieves consistent sealing results, minimizes product spoilage, and offers a practical solution for medium-volume operations.

Rugged Construction for Reliability

Built from mild steel, this semi-automatic machine withstands the rigors of industrial use. Its robust design ensures longevity, while the electric drive system delivers dependable performance with every sealing cycle. With a one-year warranty, users are assured of lasting quality and support.

Streamlined Packaging Process

The semi-automatic mechanism simplifies operationallowing efficient control by operators without a need for computerized systems. This design makes the machine accessible and straightforward, especially within busy supari packaging environments where speed and reliability are paramount.

FAQs of supari packaging machine(vacuum sealing machine):

Q: How does the supari packaging machine improve product shelf-life?

A: By vacuum sealing each packet, the machine reduces exposure to air and moisture, thereby preserving the flavor and freshness of supari for longer periods. This process effectively prevents spoilage and extends shelf life during storage and distribution.Q: What is the recommended industrial usage for this vacuum sealing machine?

A: The machine is ideal for industrial-scale supari packaging operations, including those run by distributors, manufacturers, and exporters seeking efficient, semi-automatic sealing of their products in large volumes.Q: Where can the supari packaging machine be installed?

A: The machine is suited for installation in factories, packaging plants, and warehouses across India, wherever industrial bulk supari packaging is required.Q: What is the step-by-step process for operating the supari packaging machine?

A: Operators place the supari packets into the machine, activate the vacuum sealing function using an electric switch, and once the cycle is complete, remove the sealed packets. The semi-automatic design requires minimal setup and monitoring during operation.Q: When should routine maintenance be performed on the packaging machine?

A: Routine maintenance is recommended every few weeks or after every 20 m/hr packaging cycle to ensure optimal performance, with special attention to cleaning the vacuum chamber and checking electrical connections.Q: What are the main benefits of using this supari packaging machine for industrial purposes?

A: The key benefits include enhanced efficiency in packaging, consistent sealing quality, improved product longevity, and reduced manual labor due to the semi-automatic operation.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VACUUM Packing Machine Category

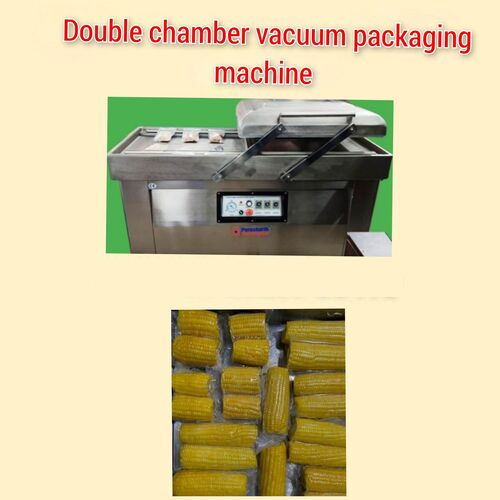

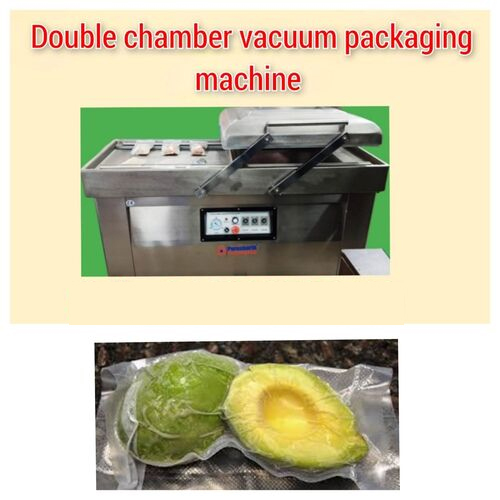

Double Chamber Vacuum Packaging Machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1

Drive Type : Electric

Automatic Grade : SemiAutomatic

Material : Stainless Steel

Color : Other

sweet corn packing machine

Price 198500 INR / Unit

Minimum Order Quantity : 01 Unit

Drive Type : Electric

Automatic Grade : Automatic

Material : Stainless Steel

Color : Silver

avocado vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Drive Type : Electric

Automatic Grade : SemiAutomatic

Material : Stainless Steel

Color : Silver

Shrink Packing Machine

Price 48500.00 INR / Unit

Minimum Order Quantity : 1 , , Unit

Drive Type : Electric

Automatic Grade : SemiAutomatic

Material : Mild Steel

Color : Blue

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry