Tooth Brush Blister Packing machine

Price 90000.0 INR/ Unit

Tooth Brush Blister Packing machine Specification

- Application

- Tooth Brush Blister Packing

- Features

- Plate size: 18 x 26 inches

- Power Supply

- Electric

- Usage

- Blister Packaging of Toothbrush

- Feature

- Other

- Computerized

- No

- Drive Type

- Other

- Power

- 1 PH - 250V Volt (v)

- Voltage

- 250V Volt (v)

- Weight (kg)

- 160 kg Kilograms (kg)

- Dimension (L*W*H)

- 20 x 50 x 37 inches Inch (in)

- Sealing Type

- Other

Tooth Brush Blister Packing machine Trade Information

- Minimum Order Quantity

- 1 Unit

- Supply Ability

- 1000 Units Per Month

- Delivery Time

- 7 Days

About Tooth Brush Blister Packing machine

To ensure hygiene and protection, toothbrushes are packaged in blister packets using a Toothbrush Blister Packing Machine. It runs on 230V, 1 PH electricity. The heating unit, forming die, sealing station, cutting mechanism, and film feeding system are important parts. Both fully automatic and semi-automatic variants are available. Utilising cutting-edge design technology, the machine offers robust performance with less waste and excellent precision and efficiency. It guarantees safe, impenetrable packaging, making it perfect for sectors including retail, personal care, and healthcare. Features that improve productivity and packing quality include easy operation, rapid changeovers, and customisable blister sizes.

- Plate size : 18 x 26 inch

- Power : 1 PH 230V

- Hydraulic operated (1.5 HP Pump

- L x W x H ( 20 x 50 x 37 ) INCH

- Approx weight : 160 KG

High-Speed Automatic Toothbrush Blister Packaging Machine

This advanced machine is the dedicated solution for manufacturers of manual toothbrushes, electric toothbrush heads, dental floss, and other oral care accessories. It is engineered to deliver sterile, tamper-evident, and aesthetically appealing blister packaging essential for the hygiene-sensitive consumer market.

Key Advantages for Oral Care Products

-

Hygienic Security: The machine creates a hermetic, tamper-evident seal, ensuring the toothbrush remains sterile and protected from dust, moisture, and contamination from the production line to the point of use.

-

Optimal Product Visibility: The custom-formed, clear plastic blister maximizes exposure of the toothbrush head, handle design, and bristles, allowing the consumer to easily evaluate the product without compromising the packaging seal.

-

High-Volume Throughput: Designed for continuous operation, this high-speed system automates the forming, loading, and sealing processes, significantly increasing production capacity and reducing labor costs.

-

Versatile Tooling: Quickly accommodates a wide range of toothbrush shapes, sizes, and packaging styles (single packs, dual packs, or travel kits) through easily interchangeable molds and sealing dies.

Operational Features

The machine typically employs a seamless, multi-station workflow:

-

Forming Station: Precisely heats and vacuum-molds PVC/PET film into cavities matching the toothbrushs exact shape.

-

Product Loading: Advanced systems use automated pick-and-place robots or custom feeders to accurately insert the toothbrushes into the formed blister at high speeds.

-

Sealing Station: Applies precise heat and pressure to permanently fuse the blister plastic to the heat-seal coated backing card, guaranteeing a strong, retail-grade bond.

-

Punching/Cutting: A final die-cutting unit cleanly separates the finished blister packs and punches the required hanger hole for merchandising.

Robust Toothbrush Packaging Solution

Our Tooth Brush Blister Packing Machine provides a reliable and efficient solution for packaging toothbrushes in blisters, enhancing product safety and presentation. Its sturdy design and sizable plate allow for versatility in handling various toothbrush designs and volumes, making it suitable for both small and large-scale production environments.

Optimized for Industrial Use

Engineered for manufacturers, exporters, and suppliers, this blister packing machine operates on a standard 250V electric supply and is constructed for long-term durability. Its convenient size and weight facilitate integration into diverse production layouts without demanding excessive space or infrastructure changes.

FAQs of Tooth Brush Blister Packing machine:

Q: How does the Tooth Brush Blister Packing Machine operate?

A: The machine uses electric power (1 PH 250V) to seal toothbrushes in blister packs securely. Operators manually load the toothbrushes and blisters onto the plate (18 x 26 inches), and the machine completes the packaging cycle efficiently with consistent results.Q: What products can be packaged using this machine?

A: This machine is specially designed for blister packaging of toothbrushes, accommodating different sizes and shapes due to its large plate size, making it adaptable for various product lines in the oral care industry.Q: When should I use a blister packaging machine for toothbrushes?

A: Utilize this machine whenever you need tamper-proof, professional, and visually appealing packaging for toothbrushes. Its especially beneficial in high-volume manufacturing, exporting, and supplying environments where packaging speed and consistency are critical.Q: Where can the Tooth Brush Blister Packing Machine be installed?

A: Given its moderate dimensions (20 x 50 x 37 inches) and reasonable weight (160 kg), the machine can be installed in most production or packaging facilities with standard electric supply (250V) in India and internationally.Q: What is the packing process with this machine?

A: The process involves placing the toothbrush and blister materials onto the plate, after which the machine seals the blister using heat and pressuredelivering a secure, professionally packaged toothbrush ready for distribution.Q: What are the key benefits of this blister packing machine?

A: Major benefits include enhanced packaging speed, dependable product protection, improved shelf appeal, and compatibility with a variety of toothbrush sizes, making it a valuable asset for businesses focused on quality packing and market competitiveness.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in BLISTER PACKING MACHINE Category

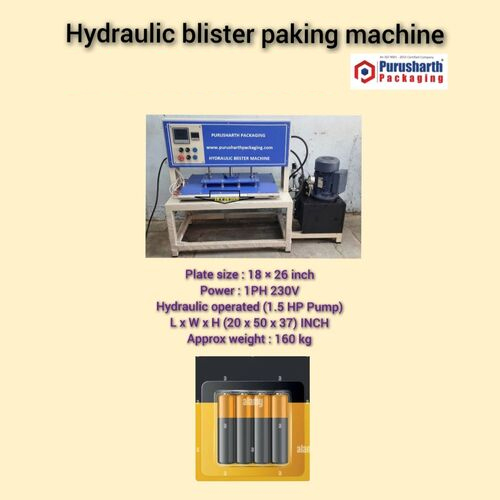

Battery cell packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 01 Unit

Features : Hydraulic system durable design

Application : Battery Cell Packing

Automatic Grade : SemiAutomatic

Usage : Battery cell packing

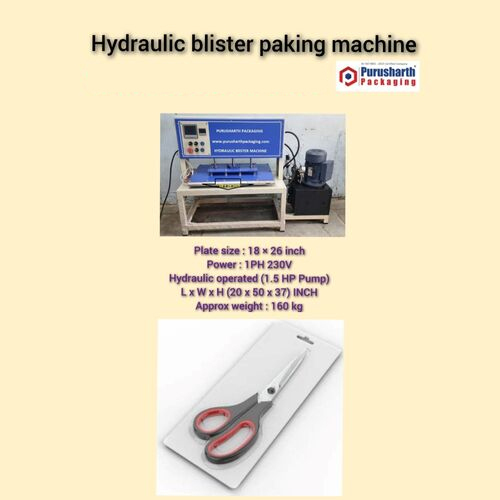

Scissors packing machine

Price 98500 INR / Unit

Minimum Order Quantity : 01 Unit

Features : Plate size: 18 x 26 inch

Application : Blister packaging for scissors

Automatic Grade : Other, Hydraulic

Usage : Scissors packaging

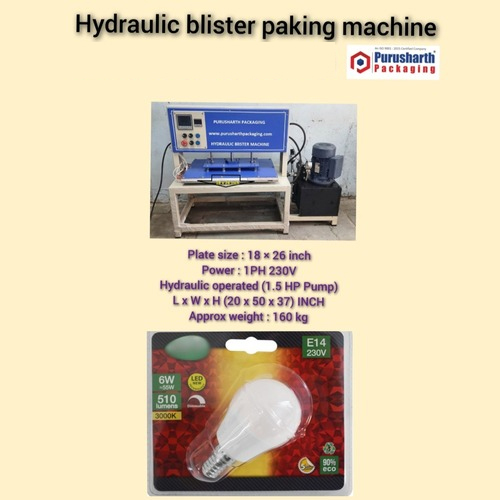

Led Bulb Blister Packing Machine

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Plate Size: 18 x 26 inch

Application : Blister Packaging for LED Bulbs

Automatic Grade : SemiAutomatic

Usage : Blister packing of LED Bulbs

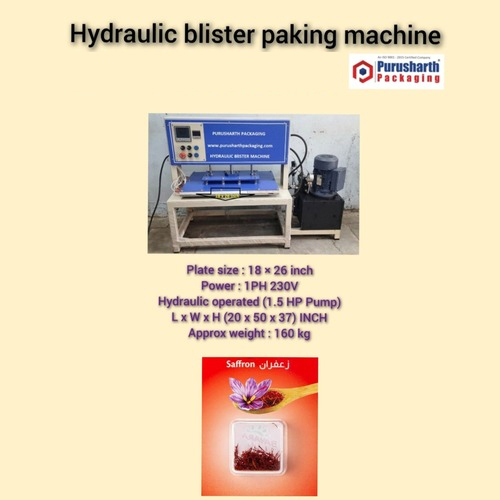

Saffron Blister Packing Machine

Price 90000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Features : Plate size 18 x 26 inches; Hydraulic operation

Application : Blister packing for saffron

Automatic Grade : SemiAutomatic

Usage : Saffron blister packaging

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry