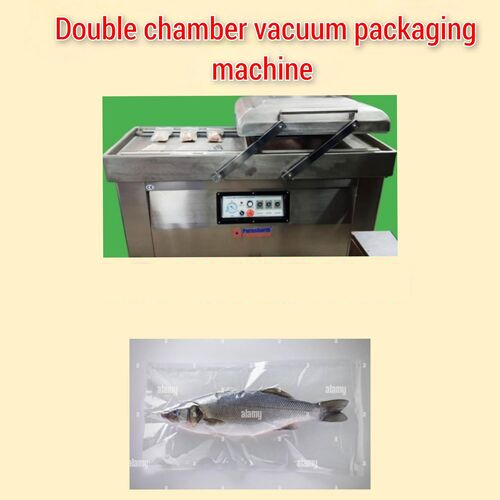

Fish packing machine

Price 198500 INR/ Unit

Fish packing machine Specification

- Application

- Fish packing machine

- Features

- Vacuum sealing for food preservation

- Usage

- Food preservation and fish packaging

- Type

- Vacuum Packaging Machine

- Material

- Stainless steel

- Feature

- Double chamber operation

- Auxiliary Packaging Machine Type

- Double chamber vacuum packaging machine

- Computerized

- Yes

- Automatic Grade

- Automatic

- Control System

- Digital Control Panel

- Drive Type

- Vacuum sealing

- Color

- Silver

- Sealing Type

- Vacuum Sealing

About Fish packing machine

VACUUM CHAMBER STAINLESS STEEL FLAT WORKING PLATE

SEALING LENGTH : 620 X 10 mm

CAPACITY 40 m 3/h

CYCLE TIME 10-40 sec.

VOLTAGE 3 PHASE 380 V/50 Hz

POWER 1.5 KW & 3.1 KW

MACHINE SIZE 1450 x 750 x 1000 mm

WORKROOM SIZE 670 x 540 x 110 mm

WEIGHT 320 KG

Robust Double Chamber Design

The fish packing machine features a sturdy double chamber mechanism, enabling simultaneous packaging processes for enhanced productivity. This design is ideal for commercial food manufacturers requiring efficient and rapid vacuum sealing to maintain product freshness and meet demanding output targets.

Advanced Vacuum Technology

Utilizing sophisticated vacuum sealing technology, this packaging machine minimizes air exposure, crucial for preserving the quality and flavor of fish and other perishables. The result is extended shelf life and reduced spoilage, making it an essential tool for food industry professionals.

Digital Control Panel Operation

Integrated with a user-friendly digital control panel, operators can easily calibrate and oversee every aspect of the packaging process. This system guarantees consistent sealing, optimized vacuum levels, and reliable, automated performance batch after batch.

FAQs of Fish packing machine:

Q: How does the double chamber vacuum packaging machine preserve fish?

A: The machine utilizes advanced vacuum sealing technology to remove air from the packaging chamber before sealing. This process inhibits bacterial growth and oxidation, significantly extending the freshness and shelf life of fish and other food products.Q: What is the operational process for this fish packing machine?

A: Operators load fish into the designated chamber, set parameters on the digital control panel, and initiate the cycle. The machine then creates a vacuum environment, seals the package, and repeats the process in the second chamber for continuous high-volume output.Q: When should I use a double chamber vacuum packaging machine for food preservation?

A: The machine is ideal when you require efficient, large-scale packaging for perishable items like fish. Its especially beneficial for businesses aiming to maximize shelf life, maintain product quality, and reduce spoilage during transportation or storage.Q: Where is this vacuum sealing machine commonly used in India?

A: This vacuum packaging machine is widely employed in food processing industries, seafood export units, and distribution centers across India. Its supplied through a network of distributors, exporters, manufacturers, and other industry professionals.Q: What are the benefits of stainless steel construction in this packaging machine?

A: The stainless steel build offers exceptional durability, corrosion resistance, and ease of cleaning, which is vital for maintaining hygiene standards in food processing environments.Q: How does the digital control panel enhance the packaging process?

A: The computerized digital control system allows precise adjustment of vacuum and sealing parameters, ensuring optimal performance, consistent quality, and simplified batch control for operators.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VACUUM Packing Machine Category

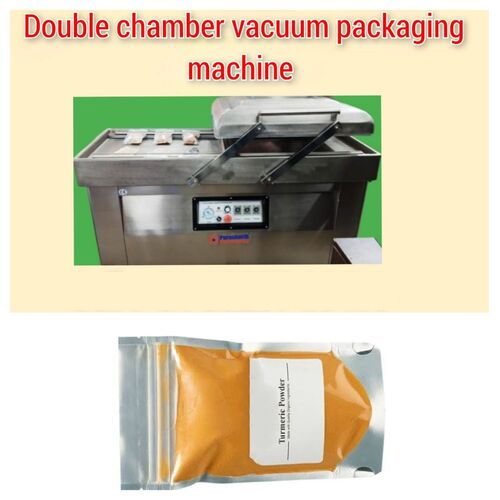

turmeric powder vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Drive Type : Electric

Material : Stainless steel

Automatic Grade : Automatic

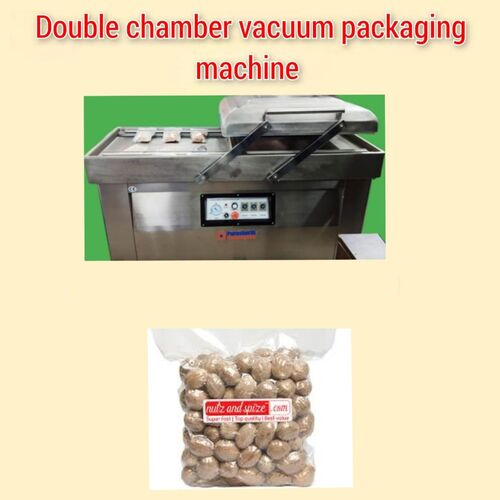

nutmeg vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Drive Type : Electric

Material : Stainless Steel

Automatic Grade : Automatic

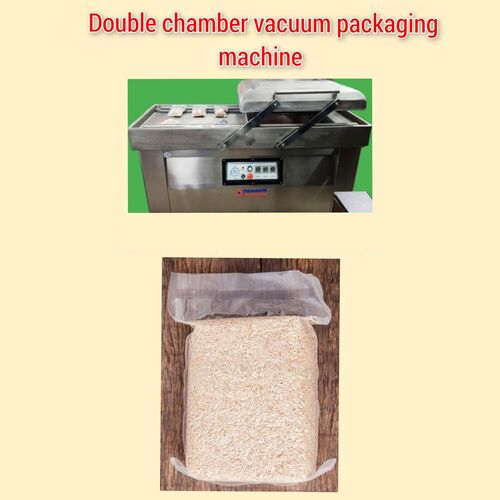

rice vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Drive Type : Electric

Material : Stainless steel

Automatic Grade : Automatic

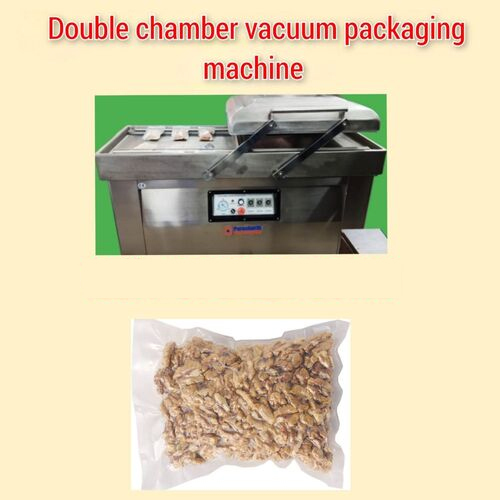

walnut vacuum packing machine

Price 150000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Color : Silver

Drive Type : Electric

Material : Stainless steel

Automatic Grade : Automatic

|

PURUSHARTH PACKAGING

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry